Professional Documents

Culture Documents

Industrial Safety

Uploaded by

Shubham KadlagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Safety

Uploaded by

Shubham KadlagCopyright:

Available Formats

INDUSTRIAL SAFETY

Industrial Safety is primarily a management activity which is concerned with reducing, controlling and eliminating hazards from the industries or industrial units.

Objectives of Industrial Safety:

Prevent accidents Eliminate work stoppage / loss of production Reduce direct and indirect costs Prevent harm to human being

Safety Organization

Essential elements: - Management Leadership - Assignment of Responsibility - Maintenance of Safe Working Conditions - Establishment of Safety Training - Accident Record System - Medical & First Aid System

Engineering

Encouragement

Safety program

Education

Enlistment

Importance of Electrical Safety Prevent Short-circuiting Equipment Prevent Fires Prevent Injury at Work Prevent Financial Loss Prevent Data Loss in Case of Computers

Activities to Achieve Industrial Safety TPM (Total Productive Maintenance) - What does it means ? - Process of the TPM - Goal of the TPM

FIVE S - Sort - Set in Order - Shine - Standardize - Safety

OHSAS (Occupational Health & Safety) - What is OHSAS ? - How they work ? - Compatibilities - Application & Benefits

Safety Audit - Audit is a Management Tool - Objectives - Types of Audit - Methodology in Conducting Safety Audit

Fire Extinguishers Types: - ABC - Water, CO2 - Dry Chemical Powder - Carbon Dioxide - Mechanical Foam

Accident & Prevention Causes of Accidents: 1) Unsafe Acts: - Use defective and unsafe tools. - Use of tools or equipment too close to energized parts. - Not draining off stored energy in capacitors. - Overloading outlets with too many appliances.

2) Unsafe Equipment: - Loose connections - Faulty insulation - Improper grounding (removal of 3rd prong) - Defective parts - Unguarded live parts

3) Hazardous Environment: An accidental static discharge can cause a fire or explosion in areas where the following are present: - Flammable vapors, liquids and gasses - Combustible dusts - Corrosive atmospheres - Explosive environments - Poor housekeeping

Principles to Prevent Accident - To prevent injury to the premature death of employees. - Reduce operation and production costs. - Have good employee employer relations. - High up the moral of employees above all the prevention of accidents. - Use of personal protective devices. - Safety activities in organization.

Workplace Safety & Health Act - What it covers ? - Workplace Safety & Health Framework - About the Act

Do Place Warning Board on main switch Before working make sure that controlling switches are opened Always treat circuit as alive Test protective equipment periodically

Dont Do not close any switch unless you are familiar with the circuit Do not touch any electrical conductor unless you have made sure that it is dead Do not work on live circuit without express order Do not use metal case flash light around apparatus which is energized

Place rubber mats in front of electrical panels

Do not place any part of your body on ground when you are working on circuits

Personal Protective Equipment

Height ? Speed ?

Safety Belt Seat Belt

Sound ?

Electricity ?

Ear Plug

Insulated Tools

Shop Floor ?

Heat ?

Safety Shoes

Apron

Grinding / Welding ?

Working on Machines ?

Goggles

Tight Cloths

Electrical Safety Models

Married Joint

Western Union Joint

Electrical Safety Models

T- Joint

Test Lamp

Electrical Tools

Electrical Screwdriver

Electrical Hammer

You might also like

- Method Statement of Static Equipment ErectionDocument20 pagesMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- SQL-Problems Solutions PDFDocument11 pagesSQL-Problems Solutions PDFManpreet Singh100% (1)

- Sika Seal-410 PG (Curing Agent) - SDS - AE - 180719Document13 pagesSika Seal-410 PG (Curing Agent) - SDS - AE - 180719usman khalid100% (1)

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Avoiding Electrocution HazardsDocument11 pagesAvoiding Electrocution HazardsJojolasNo ratings yet

- Electrical Safety OwnDocument51 pagesElectrical Safety OwnAtul BeharwalNo ratings yet

- Basic Electrical SafetyDocument28 pagesBasic Electrical SafetyKopi143No ratings yet

- ES Audit CheckpointsDocument12 pagesES Audit CheckpointsAnonymous j5apk2AumNo ratings yet

- NEPRA Power Safety Code GuidelinesDocument23 pagesNEPRA Power Safety Code GuidelinesEngr Imtiaz Hussain GilaniNo ratings yet

- Safety Roles and ResponsibilitiesDocument26 pagesSafety Roles and ResponsibilitiesAlvin Garcia Palanca100% (1)

- Basic Electrical SafetyDocument19 pagesBasic Electrical SafetySAYEDNo ratings yet

- 2 Gall - Electrical SafetyDocument72 pages2 Gall - Electrical SafetyYounes Akakba100% (1)

- Hazardous Engineering Solutions - Feb 2013Document40 pagesHazardous Engineering Solutions - Feb 2013michael3511No ratings yet

- Safety Precautions and Safety Procedures For Maintenance of Circuit BreakersDocument10 pagesSafety Precautions and Safety Procedures For Maintenance of Circuit BreakersSayed NagyNo ratings yet

- Electrical Safety: Click To Edit Master Title StyleDocument26 pagesElectrical Safety: Click To Edit Master Title StyleDelson Jon Herrera BonifacioNo ratings yet

- Organisation Study On SHREE CEMENT BEAWARDocument89 pagesOrganisation Study On SHREE CEMENT BEAWARRajesh YadavNo ratings yet

- HSE Manual 01Document16 pagesHSE Manual 01Arman Ul NasarNo ratings yet

- Basic Electrical SafetyDocument25 pagesBasic Electrical Safetyperezes100% (1)

- Chemical Disaster Mock Exercise ReportDocument34 pagesChemical Disaster Mock Exercise ReportYogendra KatiyarNo ratings yet

- Saline Water Desalination Electrical Work ChecklistDocument1 pageSaline Water Desalination Electrical Work ChecklistBRC HSE Dept.No ratings yet

- Electrical Hazards Safety GuideDocument23 pagesElectrical Hazards Safety GuideAditya PrawiraNo ratings yet

- CCOHS: Canada's National Resource for Workplace Health and SafetyDocument21 pagesCCOHS: Canada's National Resource for Workplace Health and SafetylussianaNo ratings yet

- Hira PDFDocument69 pagesHira PDFvinod100% (1)

- Safety Guidelines For Electrical High VoltageDocument6 pagesSafety Guidelines For Electrical High VoltageJeck SabarNo ratings yet

- 14.electrical SafetyDocument30 pages14.electrical SafetyZulkarnaenUchihaNo ratings yet

- Final Exam - Industrial Hygiene - Bsese 5aDocument2 pagesFinal Exam - Industrial Hygiene - Bsese 5aMike Mor'zNo ratings yet

- Industrial Risk Assessment Using ALOHADocument16 pagesIndustrial Risk Assessment Using ALOHAadwitiya1No ratings yet

- Electrical Hazards: Effects of Electric Shock & Arc FlashDocument13 pagesElectrical Hazards: Effects of Electric Shock & Arc FlashShubham SaksenaNo ratings yet

- Portable Equp MNT GuideDocument0 pagesPortable Equp MNT GuideashawishNo ratings yet

- Presentation Session 1Document22 pagesPresentation Session 1Hamza Al-QuqaNo ratings yet

- Arc Flash Hazard Analysis and Mitigation PaperDocument20 pagesArc Flash Hazard Analysis and Mitigation PapergjanitoNo ratings yet

- Module-2 Fire SafetyDocument19 pagesModule-2 Fire SafetyBuddies Da Neeghe PuroNo ratings yet

- Electrical Safety SignsDocument28 pagesElectrical Safety SignsAllan Soldevilla BitonNo ratings yet

- 10EE761 - Unit 1 Intro To PSPDocument37 pages10EE761 - Unit 1 Intro To PSPsrinimeha@gmail.comNo ratings yet

- F A Q On Industrial SafetyDocument10 pagesF A Q On Industrial SafetySafetybossNo ratings yet

- Job Safety Analysis for Nitrogen Plant OperationDocument2 pagesJob Safety Analysis for Nitrogen Plant OperationVi VekNo ratings yet

- Electrical Safety PresentationDocument19 pagesElectrical Safety PresentationMutahirrasoolNo ratings yet

- Permit Work System SafetyDocument36 pagesPermit Work System SafetyDipin RajNo ratings yet

- FATAL RISK ConstructioniDocument10 pagesFATAL RISK ConstructioniraghuvarmaNo ratings yet

- Arc Flash HazardsDocument19 pagesArc Flash HazardsAhmed MostafaNo ratings yet

- Fire Alarm Ert Staff Training Course - 01Document53 pagesFire Alarm Ert Staff Training Course - 01YounisQamarNo ratings yet

- TIS-HSE FRM-26 HSE Award Nomination FormDocument1 pageTIS-HSE FRM-26 HSE Award Nomination FormSyed Ahmed manzoor100% (1)

- Why The Focus On Arc Flash?Document8 pagesWhy The Focus On Arc Flash?jesusbarajasNo ratings yet

- Electrical Apparatus For Explosive Atmosphere (ETD 22) - Electrotechnical Division-Public Safety Standards of IndiaDocument4 pagesElectrical Apparatus For Explosive Atmosphere (ETD 22) - Electrotechnical Division-Public Safety Standards of IndiamaninderpreetNo ratings yet

- Risk Matrices Implied Accuracy and False Assumptions PDFDocument8 pagesRisk Matrices Implied Accuracy and False Assumptions PDFAnonymous FmXEu2cHxKNo ratings yet

- Safety To Be Followed While Using Electrical EquipmentsDocument52 pagesSafety To Be Followed While Using Electrical Equipmentsvmanjeer_510521687No ratings yet

- Safety Management - PDFDocument43 pagesSafety Management - PDFMansi PatelNo ratings yet

- Electrical System ProtectionDocument18 pagesElectrical System Protectionbiju singhNo ratings yet

- Radiation Safety: ἄτομος or átomos meaning "indivisible") is the smallest particle of aDocument10 pagesRadiation Safety: ἄτομος or átomos meaning "indivisible") is the smallest particle of adypietNo ratings yet

- Safety Incentive Programs: Safety and Health Resource ManualDocument7 pagesSafety Incentive Programs: Safety and Health Resource ManualNorthNo ratings yet

- ARC Flash Protective ClothingDocument10 pagesARC Flash Protective ClothingJimmy KodiatNo ratings yet

- Electrical Safety: Assignment No. 10Document21 pagesElectrical Safety: Assignment No. 10waqashabib100% (1)

- Accident Prevention Course OverviewDocument255 pagesAccident Prevention Course OverviewEliana J Yazo CNo ratings yet

- Safety Park BungeDocument37 pagesSafety Park BungeRavi Sankar VenkatesanNo ratings yet

- Electrical Safety TrainingDocument52 pagesElectrical Safety Trainingmadhulika100% (1)

- 11 Electrical SafetyDocument30 pages11 Electrical SafetyPrakash RaoNo ratings yet

- Why engineers must study Basic Occupation Safety and Health (BOSHDocument8 pagesWhy engineers must study Basic Occupation Safety and Health (BOSHCarl Vincent TaboadaNo ratings yet

- Chemical Engineering Safety PrinciplesDocument106 pagesChemical Engineering Safety PrinciplesAFEC AGIRONo ratings yet

- Industrial Safety and Hazard ManagementDocument89 pagesIndustrial Safety and Hazard ManagementRoshanNo ratings yet

- Bosh ReviewerDocument11 pagesBosh ReviewerRanvelle PeñaNo ratings yet

- Engineering Safety in DesignDocument16 pagesEngineering Safety in DesignhashimtkmceNo ratings yet

- CSS11 Q1 09-12Document11 pagesCSS11 Q1 09-12Mindanao Community SchoolNo ratings yet

- Sr. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41Document30 pagesSr. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41Shubham KadlagNo ratings yet

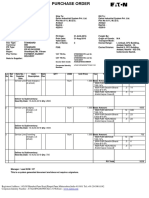

- Accurate Engineering Co PVT LTD - Standard - PO No 941600728Document3 pagesAccurate Engineering Co PVT LTD - Standard - PO No 941600728Shubham KadlagNo ratings yet

- Deepa Dsrgter4tDocument3 pagesDeepa Dsrgter4tShubham KadlagNo ratings yet

- Examresult SBI Probationary OfficersDocument2 pagesExamresult SBI Probationary OfficersJayesh VasavaNo ratings yet

- Hologram PresentationDocument8 pagesHologram PresentationShubham KadlagNo ratings yet

- Sbi Po Interview ScheduleDocument1 pageSbi Po Interview ScheduleShubham KadlagNo ratings yet

- A Seminar Report ON: HolographyDocument16 pagesA Seminar Report ON: HolographyShubham KadlagNo ratings yet

- Pune Vidyarthi Griha's COET admission formDocument2 pagesPune Vidyarthi Griha's COET admission formShubham KadlagNo ratings yet

- Pune1 WPC May 2013 Sales Report by DistributorDocument2 pagesPune1 WPC May 2013 Sales Report by DistributorShubham KadlagNo ratings yet

- Readme En-UkDocument9 pagesReadme En-UkFatma ZekajNo ratings yet

- MotherboardDocument8 pagesMotherboardSudarsan JaganathanNo ratings yet

- 2013 Marathi CalendarDocument12 pages2013 Marathi CalendarShubham KadlagNo ratings yet

- Meaning of NameDocument1 pageMeaning of NameShubham KadlagNo ratings yet

- TimetableDocument4 pagesTimetableShubham KadlagNo ratings yet

- AIEEE 2012 Information BrochureDocument53 pagesAIEEE 2012 Information Brochuresd11123No ratings yet

- Waste TreatmentDocument48 pagesWaste TreatmentShubham KadlagNo ratings yet

- BITSAT2012 BroucherDocument19 pagesBITSAT2012 BroucherShubham AgrawalNo ratings yet

- Bubble Sort Pseudocode and FlowchartDocument2 pagesBubble Sort Pseudocode and Flowchartblackcoder4150% (8)

- UPSC announces Special Class Railway Apprentices' Exam 2011Document9 pagesUPSC announces Special Class Railway Apprentices' Exam 2011Shubham KadlagNo ratings yet

- Method StatementDocument11 pagesMethod StatementMohammad Fazal Khan100% (1)

- The Basic New Keynesian Model ExplainedDocument29 pagesThe Basic New Keynesian Model ExplainedTiago MatosNo ratings yet

- Recommended lubricants and refill capacitiesDocument2 pagesRecommended lubricants and refill capacitiestele123No ratings yet

- Curriculum Vitae 2010Document11 pagesCurriculum Vitae 2010ajombileNo ratings yet

- Vydyne® R533H NAT: Ascend Performance Materials Operations LLCDocument4 pagesVydyne® R533H NAT: Ascend Performance Materials Operations LLCJames FaunceNo ratings yet

- Laporan Mutasi Inventory GlobalDocument61 pagesLaporan Mutasi Inventory GlobalEustas D PickNo ratings yet

- The Power of Flexibility: - B&P Pusher CentrifugesDocument9 pagesThe Power of Flexibility: - B&P Pusher CentrifugesberkayNo ratings yet

- Master StationDocument138 pagesMaster StationWilmer Quishpe AndradeNo ratings yet

- Joint Memorandum Circular (JMC) No. 2021Document49 pagesJoint Memorandum Circular (JMC) No. 2021Nicey RubioNo ratings yet

- Nexus Undercarriage Cross Reference GuideDocument185 pagesNexus Undercarriage Cross Reference GuideRomanNo ratings yet

- Job Hazard Analysis TemplateDocument2 pagesJob Hazard Analysis TemplateIzmeer JaslanNo ratings yet

- Broadband BillDocument1 pageBroadband BillKushi GowdaNo ratings yet

- 702190-Free PowerPoint Template AmazonDocument1 page702190-Free PowerPoint Template AmazonnazNo ratings yet

- Article 4Document31 pagesArticle 4Abdul OGNo ratings yet

- Oscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionDocument6 pagesOscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionOscar Ortega LopezNo ratings yet

- Business PlanDocument9 pagesBusiness PlanRico DejesusNo ratings yet

- Maintenance: ASU-600 SeriesDocument54 pagesMaintenance: ASU-600 SeriesMichael Maluenda Castillo100% (2)

- The Earthing of Zenner BarrierDocument4 pagesThe Earthing of Zenner BarrierFatholla SalehiNo ratings yet

- Triblender Wet Savoury F3218Document32 pagesTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentDocument12 pagesPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonNo ratings yet

- ETP Research Proposal Group7 NewDocument12 pagesETP Research Proposal Group7 NewlohNo ratings yet

- CCTV8 PDFDocument2 pagesCCTV8 PDFFelix John NuevaNo ratings yet

- Accident Causation Theories and ConceptDocument4 pagesAccident Causation Theories and ConceptShayne Aira AnggongNo ratings yet

- Courier - Capstone WebApp - Round 3 ReportDocument23 pagesCourier - Capstone WebApp - Round 3 Reportmarmounette26No ratings yet

- Hollow lateral extrusion process for tubular billetsDocument7 pagesHollow lateral extrusion process for tubular billetsjoaopedrosousaNo ratings yet

- De Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015Document10 pagesDe Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015nguyen ngaNo ratings yet

- NDU Final Project SP23Document2 pagesNDU Final Project SP23Jeanne DaherNo ratings yet

- Kunci Jawaban Creative English 3BDocument14 pagesKunci Jawaban Creative English 3BLedjab Fatima67% (3)