Professional Documents

Culture Documents

Controller Principle

Uploaded by

Portia ShilengeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controller Principle

Uploaded by

Portia ShilengeCopyright:

Available Formats

On-off Controllers

Simple

Cheap

Used In residential heating and domestic refrigerators

Limited use in process control due to continuous

cycling of controlled variable excessive wear

on control valve.

Example 1: Temperature control of jacketed vessel.

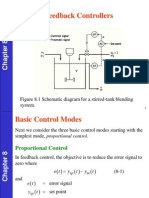

Feedback Controllers

1

On-Off Controllers

Synonyms:

two-position or bang-bang controllers.

Controller output has two possible values.

2

Three Mode (PID) Controller

Proportional

Integral

Derivative

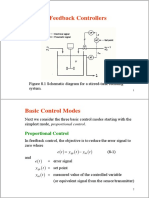

Proportional Control

Define an error signal, e, by e = R - B

where

R= set point

B = measured value of the controlled variable

(or equivalent signal from transmitter)

3

Since signals are time varying,

e(t) = R(t) - B(t)

n.b. Watch units!!

For proportional control:

where,

p(t) = controller output

= bias value (adjustable)

K

c

= controller gain (dimensionless, adjustable)

p - p = p e(t) K + p = p(t)

c

'

p

4

- Proportional Band, PB

- Reverse or Direct Acting Controller

- K

c

can be made positive or negative

- Recall for proportional FB control:

or

- Direct-Acting (K

c

< 0)

output increases as input increases"

p(t) B(t)

- Reverse-Acting (K

c

> 0)

output increases as input decreases"

c

K

% 100

PB

e(t) K + p = p(t)

c

| | B(t) - R(t) K + p = p(t)

c

5

- Transfer Function for Proportional Control:

Let

Then controller input/output relation can be written as

At zero steady state

Take Laplace transform of each side,

or

INTEGRAL CONTROL ACTION

Synonyms: "reset", "floating control"

t

1

reset time (or integral time) - adjustable

p - p(t) (t) p

'

e(t) K (t) p

c

'

E(s) K (s) P

c

'

c

K

E(s)

(s) P

'

s

1

E(s)

(s) P

t d ) t ( e

1

p ) t ( p

I

t

0 I

t

=

'

' '

t

+ =

}

6

(

' '

t

+ + =

}

t

0 I

c

t d ) t ( e

1

) t ( e K p ) t ( p

Proportional-Integral (PI) Control

Response to unit step change in e:

7

Integral action eliminates steady-state error

(i.e., offset) Why??? e = 0 p is changing with

time until e = 0, where p reaches steady state.

|

|

.

|

\

|

t

+ =

'

s

1

1 K

E(s)

(s) P

I

c

Transfer function for PI control

8

Derivative Control Action

- Ideal derivative action

- Used to improve dynamic response of the

controlled variable

- Derivative kick (use db/dt )

- Use alone?

- Some controllers are calibrated in 1/t

I

("repeats per minute") instead of t

I

.

p

dt

de

p ) t ( p

D

t + =

- For PI controllers, is not adjustable.

9

Proportional-Integral-Derivative (PID) Control

Now we consider the combination of the proportional, integral,

and derivative control modes as a PID controller.

Many variations of PID control are used in practice.

Next, we consider the three most common forms.

Parallel Form of PI D Control

The parallel form of the PID control algorithm (without a

derivative filter) is given by

( ) ( ) ( )

( )

0

1

* * (8-13)

t

c D

I

de t

p t p K e t e t dt

dt

(

= + + +

(

}

10

The corresponding transfer function is:

( )

( )

1

1 (8-14)

c D

I

P s

K s

E s s

'

(

= + +

(

Series Form of PI D Control

Historically, it was convenient to construct early analog

controllers (both electronic and pneumatic) so that a PI element

and a PD element operated in series.

Commercial versions of the series-form controller have a

derivative filter that is applied to either the derivative term, as in

Eq. 8-12, or to the PD term, as in Eq. 8-15:

( )

( )

1 1

(8-15)

1

I D

c

I D

P s

s s

K

E s s s

'

| || |

+ +

=

| |

+

\ .\ .

11

Expanded Form of PI D Control

In addition to the well-known series and parallel forms, the

expanded form of PID control in Eq. 8-16 is sometimes used:

( ) ( ) ( )

( )

0

* * (8-16)

t

c I D

de t

p t p K e t K e t dt K

dt

= + + +

}

Features of PID Controllers

Elimination of Derivative and Proportional Kick

One disadvantage of the previous PID controllers is that a

sudden change in set point (and hence the error, e) will cause the

derivative term momentarily to become very large and thus

provide a derivative kick to the final control element.

12

13

Automatic and Manual Control Modes

Automatic Mode

Controller output, p(t), depends on e(t), controller

constants, and type of controller used.

( PI vs. PID etc.)

- Manual Mode

Controller output, p(t), is adjusted manually.

- Manual Mode is very useful when unusual

conditions exist:

plant start-up

plant shut-down

emergencies

Percentage of controllers "on manual ??

(30% in 2001, Honeywell survey)

14

Digital PID Controller

where,

= the sampling period (the time between

successive samples of the controlled variable)

= controller output at the nth sampling

instant, n=1,2,

= error at the nth sampling unit

velocity form - see Equation (8-19)

(Ap

d

)- incremental change

( )

(

A

t

+

t

A

+ + =

=

1 n n

D

1 n

1 k

k

I

n c n

e e

t

e

t

e K p p

n

p

n

e

t A

15

PID -Most complicated to tune (K

c

, t

I

, t

D

) .

-Better performance than PI

-No offset

-Derivative action may be affected by noise

PI -More complicated to tune (K

c

, t

I

) .

-Better performance than P

-No offset

-Most popular FB controller

P -Simplest controller to tune (K

c

).

-Offset with sustained disturbance or set point

change.

Controller Comparison

16

17

Typical Response of Feedback Control Systems

Consider response of a controlled system after a

sustained disturbance occurs (e.g., step change in

disturbance variable)

18

19

20

Summary of the Characteristics of the Most

Commonly Used Controller Modes

1. Two Position:

Inexpensive.

Extremely simple.

2. Proportional:

Simple.

Inherently stable when properly tuned.

Easy to tune.

Experiences offset at steady state.

3. Proportional plus integral:

No offset.

Better dynamic response than reset alone.

Possibilities exist for instability due to lag

introduced.

21

4. Proportional plus derivative:

Stable.

Less offset than proportional alone (use of

higher gain possible).

Reduces lags, i.e., more rapid response.

5. Proportional plus reset plus rate:

Most complex

Rapid response

No offset.

Difficult to tune.

Best control if properly tuned.

22

Example 3: Liquid Level Control

Control valves are air-to-open

Level transmitters are direct acting

23

Question:

1. Type of controller action?

24

You might also like

- Feedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemDocument24 pagesFeedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemRama ChilpuriNo ratings yet

- PDC Chapter 8Document49 pagesPDC Chapter 8satya sagarNo ratings yet

- Feedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending SystemDocument18 pagesFeedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending Systeml7aniNo ratings yet

- Process Dynamics and Control: Chapter 8 LecturesDocument33 pagesProcess Dynamics and Control: Chapter 8 LecturesMuhaiminul IslamNo ratings yet

- Week 12 - Control SystemDocument30 pagesWeek 12 - Control SystemAzizan Anuar100% (1)

- Pid Controller: Ashok.S 500017496 M.Tech Pde R670211016Document40 pagesPid Controller: Ashok.S 500017496 M.Tech Pde R670211016Ashik Jacob Oommen100% (1)

- Feedback Controllers ExplainedDocument14 pagesFeedback Controllers Explained李承家No ratings yet

- EE448 Lec3 ControlTechniques 2014Document25 pagesEE448 Lec3 ControlTechniques 2014scotgunnerNo ratings yet

- InTech-Pid Control TheoryDocument17 pagesInTech-Pid Control TheoryAbner BezerraNo ratings yet

- Chapter 8 - Feedback ControllerDocument35 pagesChapter 8 - Feedback ControllerFakhrulShahrilEzanieNo ratings yet

- Presentation For ControllerDocument42 pagesPresentation For ControllerAlakshendra JohariNo ratings yet

- Proportional-Integral-Derivative (PID) Control: Velocity ResponseDocument34 pagesProportional-Integral-Derivative (PID) Control: Velocity ResponseFadi AlbatshNo ratings yet

- PID Controller Design for Optimal System ResponseDocument39 pagesPID Controller Design for Optimal System ResponseMani Kumar ReddyNo ratings yet

- Chapter 8Document31 pagesChapter 8fosterNo ratings yet

- Control SystemDocument48 pagesControl SystemOlawale John AdeotiNo ratings yet

- Chapter 7 - Feedback ControllersDocument44 pagesChapter 7 - Feedback ControllersPravin Nair50% (2)

- L-14 (SS) (Iac) ( (Ee) Nptel)Document10 pagesL-14 (SS) (Iac) ( (Ee) Nptel)Marvin BayanayNo ratings yet

- Introduction To PID Control: Lab-808: Power Electronic Systems & Chips Lab., NCTU, TaiwanDocument32 pagesIntroduction To PID Control: Lab-808: Power Electronic Systems & Chips Lab., NCTU, TaiwandaswkNo ratings yet

- Control of Continuous Process: Lecturer: Dr. Shallon StubbsDocument32 pagesControl of Continuous Process: Lecturer: Dr. Shallon StubbsLuther King Ferguson100% (1)

- Control System-Ii Lab File: Bachelor of Engineering (Division of Instrumentation & ControlDocument41 pagesControl System-Ii Lab File: Bachelor of Engineering (Division of Instrumentation & ControlParas SinghNo ratings yet

- Control StrategyDocument44 pagesControl StrategyAyunie FazlinNo ratings yet

- Pid Controller Tuning: S.no Name of The ChapterDocument35 pagesPid Controller Tuning: S.no Name of The ChapterAmit TripathiNo ratings yet

- ControllersDocument32 pagesControllersEric KamauNo ratings yet

- Project Based Learning IcsDocument14 pagesProject Based Learning IcsAvinash YadavNo ratings yet

- Week 10-Feedback ControlDocument34 pagesWeek 10-Feedback ControlMohd Aizad100% (1)

- Feedback Controller: Proportional, Integral, Derivative (PID)Document34 pagesFeedback Controller: Proportional, Integral, Derivative (PID)Ereen100% (1)

- Experiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETDocument18 pagesExperiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETMd Abid AfridiNo ratings yet

- Control Systems Modeling and DesignDocument37 pagesControl Systems Modeling and DesignshrnbolonneNo ratings yet

- Finn Haugen. Telemark University College National Instruments ConfidentialDocument27 pagesFinn Haugen. Telemark University College National Instruments ConfidentialtriplbingaziNo ratings yet

- Pid CernDocument98 pagesPid CernsybaritzNo ratings yet

- CHE3162 Lecture 8: Introduction to Feedback Control LoopsDocument33 pagesCHE3162 Lecture 8: Introduction to Feedback Control LoopsPhan NeeNo ratings yet

- PID Control Fundamentals ExplainedDocument56 pagesPID Control Fundamentals ExplainedSyafRizal100% (1)

- Chap 08 Marlin 2002Document37 pagesChap 08 Marlin 2002Audrey Patrick KallaNo ratings yet

- Week 9Document21 pagesWeek 9candan.erkenNo ratings yet

- Dieu TocDocument20 pagesDieu TocladoiblNo ratings yet

- Starting: Chapter 7: PID ControlDocument13 pagesStarting: Chapter 7: PID ControlKishodarran Rajendran KicchoNo ratings yet

- Repetitive ControlDocument22 pagesRepetitive ControlShri KulkarniNo ratings yet

- PID Control TheoryDocument17 pagesPID Control TheoryManuel Santos MNo ratings yet

- Pid Control ch8 PDFDocument22 pagesPid Control ch8 PDFGholamreza IlkhaniNo ratings yet

- Various Types of ControllerDocument59 pagesVarious Types of ControllerZakariyaNo ratings yet

- ExercisesDocument18 pagesExercisescetec1234No ratings yet

- P, I, D, PI, PD, and PID ControlDocument14 pagesP, I, D, PI, PD, and PID ControlArnav KothiyalNo ratings yet

- PID SIMULATOR GUIDEDocument18 pagesPID SIMULATOR GUIDEAAYUSH KUMARNo ratings yet

- Experiment No.: - 1: To Study The DC Servomotor CharacteristicsDocument50 pagesExperiment No.: - 1: To Study The DC Servomotor CharacteristicsNobita NobiNo ratings yet

- 4 Transfer FunctionDocument22 pages4 Transfer FunctionSalihin FhooziNo ratings yet

- Contro EngineeringDocument29 pagesContro EngineeringNor AshimyNo ratings yet

- Closed Loop Control System (CSL - 04) : Technical Manual FORDocument19 pagesClosed Loop Control System (CSL - 04) : Technical Manual FORAAYUSH KUMARNo ratings yet

- Task2 1 Specific Training-EnDocument35 pagesTask2 1 Specific Training-EnSantiago LarrazNo ratings yet

- Embedded Systems and Control Systems': An Open-Loop ControllerDocument5 pagesEmbedded Systems and Control Systems': An Open-Loop Controllermohed_kamalNo ratings yet

- Pid Control ExperimentDocument15 pagesPid Control Experimentazhar3303No ratings yet

- Process Chapter 3Document35 pagesProcess Chapter 3Estifanos FitsumNo ratings yet

- EEE373 Electric Motor Drive: Asst. Prof. Dr. Mongkol Konghirun Ee, KmuttDocument16 pagesEEE373 Electric Motor Drive: Asst. Prof. Dr. Mongkol Konghirun Ee, KmuttTumenbayar LkhagvatserenNo ratings yet

- ERT 321 Process Control & Dynamics: Feedback ControllersDocument34 pagesERT 321 Process Control & Dynamics: Feedback Controllershakita86No ratings yet

- 8.1. Lab ObjectiveDocument6 pages8.1. Lab ObjectiveJang-Suh Justin LeeNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsFrom EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Nonlinear Control Feedback Linearization Sliding Mode ControlFrom EverandNonlinear Control Feedback Linearization Sliding Mode ControlNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Suitable Pumps For GasolineDocument5 pagesSuitable Pumps For GasolinePortia ShilengeNo ratings yet

- UOP Reforming Solutions For .Improved Profits PaperDocument32 pagesUOP Reforming Solutions For .Improved Profits PaperstevemetroNo ratings yet

- Non Newtonian FluidsDocument12 pagesNon Newtonian FluidsPortia ShilengeNo ratings yet

- Solved Problems Samples in Fluid Flow PDFDocument10 pagesSolved Problems Samples in Fluid Flow PDFRichard Obinna100% (1)

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengeNo ratings yet

- 2011-03 Head Losses Calculations PDFDocument44 pages2011-03 Head Losses Calculations PDFAnastasia Monica KhunniegalshottestNo ratings yet

- 12 Chapter3 Section4 Oil Refining Industry Page193 220Document26 pages12 Chapter3 Section4 Oil Refining Industry Page193 220Muhammad FarooqNo ratings yet

- Caracteristicas Normas ASME B31Document3 pagesCaracteristicas Normas ASME B31darthneoNo ratings yet

- ECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Document99 pagesECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Portia ShilengeNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengeNo ratings yet

- Lecture 6Document42 pagesLecture 6Anonymous 9R53UyNo ratings yet

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeNo ratings yet

- Cive1400 200304 PDFDocument17 pagesCive1400 200304 PDFMohd Nazri SalimNo ratings yet

- Chapter 11Document36 pagesChapter 11Hamza FayyazNo ratings yet

- Cive1400 2000 01 - v2Document14 pagesCive1400 2000 01 - v2naefmubarakNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- Assignment 1-2013Document3 pagesAssignment 1-2013Portia ShilengeNo ratings yet

- Fluid PropertiesDocument32 pagesFluid Propertiesjmartinezmo100% (1)

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeNo ratings yet

- Laminar Flow and Frictional Pressure DropDocument35 pagesLaminar Flow and Frictional Pressure DropsyedmuhammadtariqueNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- Optimization of Ball Mill Lifter Profiles and Determination of Top Ball SizeDocument15 pagesOptimization of Ball Mill Lifter Profiles and Determination of Top Ball SizePortia ShilengeNo ratings yet

- Chapter 11Document36 pagesChapter 11Hamza FayyazNo ratings yet

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengeNo ratings yet

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengeNo ratings yet

- p2 Cyclone Eff ProjctDocument12 pagesp2 Cyclone Eff ProjctPortia ShilengeNo ratings yet

- Weekly Quiz 2 ML Machine Learning Great Learning Ankit PDFDocument6 pagesWeekly Quiz 2 ML Machine Learning Great Learning Ankit PDFRiddhi Sharma100% (1)

- MTBF - Report - Rambutan (-I) - V1Document15 pagesMTBF - Report - Rambutan (-I) - V1Madhuseptember2022No ratings yet

- Major DocDocument5 pagesMajor Dochnuozoar511230No ratings yet

- Pronostico de Demanda Red Inteligente Utilizando CNN-BiLSTM OptimizadoDocument12 pagesPronostico de Demanda Red Inteligente Utilizando CNN-BiLSTM OptimizadoRony Arturo Bocangel SalasNo ratings yet

- Artificial Intelligence: Long Short Term Memory NetworksDocument14 pagesArtificial Intelligence: Long Short Term Memory NetworksThành Cao ĐứcNo ratings yet

- Setlabs Briefings Business AnalysisDocument88 pagesSetlabs Briefings Business AnalysisaustinfruNo ratings yet

- Professional SummaryDocument3 pagesProfessional SummaryVijay LS SolutionsNo ratings yet

- Sathish S 18me731 2023 24 Cim Model 1Document3 pagesSathish S 18me731 2023 24 Cim Model 1srujangowdasj2002No ratings yet

- Pred MaintDocument7 pagesPred MaintoptisearchNo ratings yet

- Maintainence and ReengineeringDocument15 pagesMaintainence and ReengineeringDr. Om Kumar C.U Asst Prof - CSE DeptNo ratings yet

- Pinna Rat Nuch PhoDocument10 pagesPinna Rat Nuch PhoJeshwuelNo ratings yet

- IEEE Project Titles 2020Document293 pagesIEEE Project Titles 2020aslanNo ratings yet

- CASE Tools Automate Software DevelopmentDocument5 pagesCASE Tools Automate Software DevelopmentSharmistha Mukherjee60% (5)

- Generate Mobile App RequirementsDocument4 pagesGenerate Mobile App RequirementsSudan KhadgiNo ratings yet

- Project Management Information SystemDocument2 pagesProject Management Information Systemdev_thecoolboyNo ratings yet

- Audi CaseStudy EngDocument2 pagesAudi CaseStudy EngShams TabrezNo ratings yet

- An Introduction To Artificial Neural NetworkDocument5 pagesAn Introduction To Artificial Neural NetworkMajin BuuNo ratings yet

- Leyte Normal University: Supply Inventory Management SystemDocument7 pagesLeyte Normal University: Supply Inventory Management SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cybernetic GovernanceDocument3 pagesCybernetic Governancesuhajanan16No ratings yet

- Lab Manual-Arena-1Document11 pagesLab Manual-Arena-1Mhmd Alrashed100% (2)

- Machine LearningDocument4 pagesMachine LearningAlmir AzićNo ratings yet

- 4 Types of Classification Tasks in Machine LearningDocument14 pages4 Types of Classification Tasks in Machine LearningHarish SreenivasNo ratings yet

- The Information Systems Life CycleDocument16 pagesThe Information Systems Life CycleVani AyyadevaraNo ratings yet

- Predictive Maintenance With MatlabDocument22 pagesPredictive Maintenance With MatlabwilliamNo ratings yet

- BTP PPT Phase1Document14 pagesBTP PPT Phase1MANISH KUMARNo ratings yet

- InterlanguageDocument4 pagesInterlanguagekamran khanNo ratings yet

- Soft computing and optimization techniquesDocument1 pageSoft computing and optimization techniquessindhu-aravinda9No ratings yet

- Criticality Assessment of SparesDocument11 pagesCriticality Assessment of SparesSeelan Surendran100% (2)

- Unit-III-State Space Analysis in Discrete Time Control SystemDocument49 pagesUnit-III-State Space Analysis in Discrete Time Control Systemkrushnasamy subramaniyan100% (2)

- Unit 5 AutomationDocument39 pagesUnit 5 AutomationAndrew lingtanNo ratings yet