Professional Documents

Culture Documents

Daada

Uploaded by

Abhinav GoyalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daada

Uploaded by

Abhinav GoyalCopyright:

Available Formats

EXERCISE-1

1 c

w

= 3.0 10-6 / psi c

f

= 8.6 10-6 / psi S

wc

= .20

p

i

= 4000 psi B

oi

= 1.2417 rb/stb

p

b

= 3330 psi B

ob

= 1.2511 rb/stb

To maintain pressure at 2700 psia the

total underground withdrawal at the

producing end of a reservoir block

must equal the water injection rate at

the injection end of the block.

The total withdrawal associated with

one STB of oil is:

Bo + (R Rs)Bg rb

SOLUTION

AS, Bo + (R Rs)Bg rb

Evaluating at 2700 psia, using the PVT

data

1.2022 + (3000 401) 0.00107 = 4.0 rb

Thus to produce 10,000 stb/d oil, an

initial injection rate of 40,000 rb/d of

water will be required,

If the injection had been started at, or

above bubble point pressure, a maximum

injection rate of only 12,500 b/d of water

would have been required.

GO TO SLIDE 23

Example

Example reservoir is under consideration for a waterflood project. The

volumetric calculations of the field indicate that the areal extent of the

field is 1612.6 acres. The field is characterized by the following

properties:

Thickness h = 25 ft

Porosity = 15%

Initial water saturation S

wi

= 20%

Initial pressure pi = 2377 psi

Oil production N

p

as a function of reservoir pressure p are

given below:

The PVT properties of the crude oil system are tabulated below:

Assume that the water injection will commence

when the reservoir pressure declines to 1650 psi;

find the following:

Pressure that is required to dissolve the trapped

gas.

The required rate of water injection so as have

the production of 5000 bbl/dayt

Solution-Part -1

Step 1. Calculate initial oil in place N

N = 7758 A h (1 S

wi

)/B

oi

(22 MMSTB)

Step 2. Calculate remaining oil saturation at 1650 psi:

Step 3. Calculate gas saturation at 1650 psi:

Step 4. Calculate the trapped gas saturation from Equation-1, to give

S

gt

= 12.6%

Step 5. Calculate the gas solubility when all the trapped gas is dissolved in

the oil by applying Equation :

(S

o

= 0.619)

(S

g

=0.181 )

Step 6. Enter the tabulated PVT data with the new gas solubility of 814

scf/STB and find the corresponding pressure of approximately 2140 psi.

This pressure is identified as the pressure that is required to dissolve the

trapped gas.

Solution-Part -2

Step-1: Determine R

p

at 1650 psia.

=Bo + (R

p

Rs)Bg rb

=1.706 + (1050 657) x 0.00194

=2.46 rb or 2.5 rb

Step-2:Fimnd total withdrawal associated at 1650 Psia:

Thus the required rate will be 2.5 x 5000=12500bbl

Gp = RpNp

Factors important in WI pressure

maintenance and water flooding:

1 Reservoir Geometry

2.Lithology

3.Reservoir depth.

4.Porosity

5.Permeability (Magnitude and variation)

6.Fluid properties and Relative permeability

Relationship.

7.Continuity of reservoir rock properties

8.Magnitude and distribution of fluid saturations.

Remarks

These factors influence ultimate recovery,

rate of return and ultimate economics.

Therefore the process along with these

Factors must be considered collectively

To evaluate economic feasibility .Factors

Like oil price , marketing conditions,

operating expenses and availability of water

also influence the implementation of WI/

Pressure maintenance

EXERCISE-1

1

Determine the fractional oil recovery, during

depletion down to bubble point pressure

c

w

= 3.0 10-6 / psi c

f

= 8.6 10-6 / psi S

wc

= .20

p

i

= 4000 psi B

oi

= 1.2417 rb/stb

p

b

= 3330 psi B

ob

= 1.2511 rb/stb

Step-1:

average compressibility of the under saturated oil

between initial and bubble point pressure:

Step-2:

The recovery at bubble point pressure can be

calculated as:

SOLUTION

or 1.52% of the original oil in place

REMARKS

Considering that the 670 psi pressure drop

represents about 17% of the initial,

absolute pressure, the oil recovery is

extremely low. This is because the effective

compressibility is small providing the

reservoir contains just liquid oil and water.

The situation will, however, be quite

different once the pressure has fallen below

bubble point.

EXERCISE-2

Below bubble point pressure (saturated oil)

The reservoir described in exercise 1 will be

produced down to an abandonment pressure

of 900 psia. Determine

1. An expression for the recovery at

abandonment as a function of the

cumulative gas oil ratio Rp.

2. Derive an expression for the free gas

saturation in the reservoir at abandonment

pressure.

Assuming m = 0; no initial gas cap, negligible

water influx and not considering the equivalent

compressibility effect, the recovery factor at

abandonment pressure of 900 psia is given as:

SOLUTION

in which all the PVT parameters Bo, Rs and Bg

are evaluated at the abandonment pressure.

Using the given data the recovery factor can be

expressed as:

1

Liberated gas

2

EXERCISE-3

WATER INJECTION BELOW BUBBLE POINT PRESSURE

It is planned to initiate a water injection in

the reservoir whose PVT properties are

defined in table of Exercise-1. The

intention is to maintain pressure at the

level of 2700psia (p

b

= 3330 psia). If the

current producing gas oil ratio of the field

(R) is 3000 scf/stb, what will be the initial

water injection rate required to produce

10,000 stb/d of oil.

To maintain pressure at 2700 psia the total

underground withdrawal at the producing end of a

reservoir block must equal the water injection rate

at the injection end of the block.

The total withdrawal associated with 1 stb of oil

is:

Bo + (R Rs)Bg rb

Evaluating at 2700 psia, using the PVT data

1.2022 + (3000 401) 0.00107 = 4.0 rb

to produce 10,000 stb/d oil, an initial injection

rate of 40,000 rb/d of water will be required,

If the injection had been started at, or above bubble point

pressure, a maximum injection rate of only 12,500 b/d of water

would have been required.

SOLUTION

Exercise-1

It is planned to initiate water injection scheme in the

reservoir as per the PVT properties given in

The table below.

Intention is to maintain pressure at least of 2700 psia

(P

b

=3330psia)

If the current producing GOR of the field

is3000scf/stb.

Calculate what will be the initial water injection rate

required to produce 10,000stb/d of oil.

Essentiality

To maintain pressure (say 2700psi)

Total underground withdrawal rate from the producing end of a

reservoir rock must be equal to water injection rate at the injection

end.

The total withdrawal associated with each(1) rb of oil is given as:

B

o

+ ( R

p

- R

s

) B

g

rb

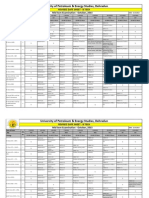

Exercise-2-PVT PROPERTIES

Pressure

[psia]

B

o

[[rb/stb]

R

s

[scf/stb]

B

g

[rb/scf]

4000 1.2417 510

3500 1.2480 510

3330(P

b

) 1.2511 510 0.00087

3000 1.2222 450 0.00096

2700 1.2022 401 0.00107

2400 1.1822 352 0.00119

2100 1.1633 304 0.00137

1800 1.1450 257 0.00161

1500 1.1287 214 0.00196

1200 1.1115 167 0.00249

900 1.0940 122 0.00339

600 1.0763 78 0.00519

300 1.0583 35 0.01065

Evaluating @2700psi and using the data of PVT

provided earlier.

B

o

+ ( R

p

- R

s

) B

g

rb

1.2511 +510 x 0.00087 rb

= 4.0 rb

Thus the total withdrawal associated with

each(1) rb of oil, for a pressure of 2700psia is

4rb(four times)

Therefore to produce 10,000 stb/d oil, the initial

water injection rate should be 40000rb/d

Calculations

(1) If the injection had been initiated at ,or above the

bubble point pressure, The requires injection rate for

water would have been 12500b/d.{10000x1.25(B

o

)}

(2) Since the water injection is now at a pressure lower than

P

b

a higher/additional injection rate of the order of

27500rb/d which amounts to{(27.5/40)x 100} =68.75%

70%of injection rate will be needed to displace the

liberated gas.

Observations

Application of PVT Studies

p. Bo. R p.

That yields oil recovery up to bubble point pressure

as .0189STB

OIL Recovery per unit STB of Oil (initial OIP) below

bubble point pressure.

That yields oil recovery @1700 psi= 0.027 STB

That yields oil recovery @1600psi = 0.048 STB

The oil saturation in the reservoir at this pressure S

o

=0.765

The Gas saturation in the reservoir at this pressure

S

g

= 0.035

1

2

A

B

below bubble point pressure

below bubble point pressure

PVT Studies

Differential liberation analysis of BHS @125F

Pressure

psig

B

o

bbl/STB

B

g

bbl/SCF

Solution

GOR

SCF/STB

B

t

bbl/STB

3100 1.4235 - 885 1.4235 B

oi

2800 1.4290 - 885 1.4290

2400 1.4370 - 885 1.4370

2000 1.4446 - 885 1.4446

1725 1.4509 - 885 1.4509 B

ob

1700 1.4468 0.00141 876 1.4595

1600 1.4303 0.00151 842 1.4952

1500 1.4139 0.00162 807 1.5403

1400 1.3978 0.00174 772 1.5444

P

i

P

b

Produced GOR

Example

Vital data:

(1) Initial reservoir pressure(@4300ftsubsea) 3100

(2) Bubble point pressure (@4300ftsubsea) 1725

(3) Average reservoir temperature 125F

(4) Average porosity 7.7%

(5) Average connate water 20%

(6) Critical gas saturation 10%

Example- Performance Prediction

Up to bubble point pressure, recovery is by expansion

of oil

When pressure falls from P

i

=3112 to p

b

=1725

i.e. for N=1 STB of oil, Np = 0.0189 STB

0189 . 0

4509 . 1

4235 . 1 4509 . 1

=

=

o

oi o

p

B

B B

N

N

For P > P

b

, the produced gas-oil-ratio at the surface

separator can be regarded as 885 SCF/STB, the initial

solution GOR

At P<P

b

, free gas phase develops.

Assumption: Free gas saturation is less than critical gas

saturation or gas remains immobile

ESSENTIALITIES

Average producing GOR between two consecutive

pressures P

1

(1725) and P

2

(1700)

R

ave

= 880.5 SCF/STB and

N

pb

=0.0189 (as determined earlier)

Let N

p1

to be determined

2

2 1 so so

avg

R R

R

+

=

=

885+876

2

At P=1700 psi

STEP-1 :

To calculate R

p

based on cumulative production up to P = 1700psia

STEP-2 :

To calculate Np1 using Material balance Equation

The calculation of R

p

based on cumulative

production up to P=1700 psia (on an

volume weighted basis) is:

1

1

5 . 880 085 . 0

p

p

p

N

N

R

+

=

Substituting in material balance equation

1

1

5 . 880 085 . 0

p

p

p

N

N

R

+

=

( )

g s si oi o g s p o p

B R R B B N B R R B N + = + ) ( ) ( ) ) ( (

1

( ) 03599 . 0 )

2415 . 1 00012 . 0

21164 . 0 (

1

1

1

N

N

N

N

p

p

p

=

+

+

Setting N to one and solving for N

p

results

that for each STB of initial oil in place we

produce

Np1=0.0247 STB(2.47%)

The determined R

p

is then substituted in MBE

To cont. prediction: At P= 1600 psig

Material balance envisages:

(Release of dissolved gas)

) ( ) (

) ( ) (

1 2 1

1 2 2 1 1

p p pb p pb

p p avg pb p avg pb soi

p

N N N N N

N N R N N R N R

R

+ +

+ +

=

Where SCF/STB

Therefore

From the material balance

Which means

Np2 = 0.0486 STB

for every 1 STB of initial OIP

859

2

842 876

2

=

+

=

avg

R

2

2

859 6161 . 0

p

p

p

N

N

R

+

=

( ) 07173 . 0 )

297 . 1 00093 . 0

1589 . 0 (

2

2

2

N

N

N

N

p

p

p

=

+

+

The oil saturation in the reservoir at this

pressure:

Oil Saturation:

Gas Saturation:

765 . 0

) 1 (

) ( ) (

2 2

=

|

.

|

\

|

=

=

wc

oi

o p o p

o

S

B N

B N N

PV

B N N

S

765 . 0 =

o

S

035 . 0 765 . 0 1 = =

wc g

S S

Rapid

Decline

Down to Pb

Flat

Curve

due to

Gas

Expan.

GRAPHICAL REPRESENTATION

The said reservoir has an areal extent of 40 acres and the

net formation thickness is 200 feet :

If the reservoir is produced at 92 BOPD, time to produce

11.35%(refer graph) of initial reserves :

MMSTB 69 . 2

4235 . 1

) 2 . 0 1 ( 077 . 0 200 7758 40

=

= N

years 08 . 9

365 92

1135 . 0 10 69 . 2

6

=

= t

Constant x, Axxh(1-S

wi

)

B

oi

N =

For pressure drop from 3112 psig to 1725 psig:

(up to bubble point)

(compared to 0.0189 without compressibility)

Performance Prediction

with compressibility effects

Additional data required/given

c

w

= 3 x 10

-6

psi-1

c

f

= 5 x 10

-6

psi-1

5 1

1.39 10

o oi

o

oi

B B

c psi

B p

= =

A

STEP-1:

CalculateC

o

( )

0284 . 0

) 1 (

=

A + +

=

o wc

oi wc w f o o p

B S

p B S c c S c

N

N

STEP-2: Apply

MBE

When pressure drops to 1700 psig, we have

already seen that :

Substituting in material balance relationship

Recovery@1700psig

1

1

5 . 880 085 . 0

p

p

p

N

N

R

+

=

|

|

|

|

|

.

|

\

|

A

|

|

.

|

\

|

+

+

+

= +

p

S

S c c

B

B R R B B

B N B R R B N

wc

wc w f

oi

g s si oi o

oi g s p o p

) 1 (

) ( ) (

) ) ( (

1

Applying MBE

3112 1700

i

p p p A = =

=1412

Substituting numbers :

Which means Np1 = 0.034 STB for every STB of

initial oil in place

(compared to 0.024 STB without

compressibility effects)

( ) 05 . 0 )

2415 . 1 00012 . 0

21164 . 0 (

1

1

1

N

N

N

N

p

p

p

=

+

+

Let p

wf

represent the maintained bottom-hole

flowing pressure at the wellbore radius r

w

and pe

denote the external pressure at the external or

drainage radius, Darcys equation as described

can be used to determine the flow rate at any

radius r is

Radial flow model

described by Darcys equation

At any point in the reservoir the

cross-sectional area across which

flow occurs will be the surface area of

a cylinder,

which is 2rh or

Minus sign is no longer required for the

radial system as the radius increases in

the same direction as the pressure.

The flow rate for a crude oil system is customarily

expressed in surface units, i.e., stock-tank barrels

(STB), rather than reservoir units.

Using the symbol Q

o

to represent the oil flow as

expressed in STB/day, then:

The flow rate in Darcys equation can be expressed in

STB/day to give:

q = B

o

Q

o

where B

o

is the oil formation volume factor bbl/STB

Integrating the above equation between two radii, r

1

and r

2

, when the pressures are p

1

and p

2

yields:

For incompressible system in a uniform formation :

On integration it yields :

If the two radii of interest are the wellbore radius r

w

and the external or drainage radius r

e

.

As the external (drainage) radius r

e

is usually

determined from the well spacing by equating the

area of the well spacing with that of a circle, i.e. r

2

e

= 43,560 A

Then

where A is the well spacing in acres

Neither the external radius nor the wellbore radius is generally known with precision.

Fortunately, they enter the equation as a logarithm, so that the error in the equation

will be less than the errors in the radii.

Pressure Oil Flow Rate

The equation:

May be given as:

The equation is used calculate the pressure profile

(distribution) and list the pressure drop across various

intervals

Where:

Example

An oil well is producing at a stabilized rate of 600 STB/day

at a stabilized bottom-hole flowing pressure of 1800 psi.

The pay zone is characterized by a permeability of 120 md

and a uniform thickness of 25ft.

The well drains an area of approximately 40 acres.

Calculate the pressure profile (distribution) and list the

pressure drop across 1 ft intervals from r

w

to 1.25 ft, 4 to

5 ft, 19 to 20 ft, 99 to 100 ft, and

744 to 745 ft.

The following additional data is available:

r

w

= 0.25 ft A = 40 acres

B

o

= 1.25 bbl/STB

o

= 2.5 cp

solution

As

In the present case:

Rearrange and solve for pressure p at radius r

STEP -1

STEP -2

Calculate the pressure at the specified

Pressure profile around the wellbore.

OIL SATURATION

or

If the reservoir has produced N

p

stock-tank barrels of oil, the

remaining oil volume is given by:

remaining oil volume = (N N

p

) B

o

or

Therefore

GAS SATURATION

S

g

= 1 S

o

S

wi

Example

Calculate the initial gas in place and the initial

reserve of a gas reservoir from the pressure

production data for a volumetric reservoir.

Initial Pressure=3250 psia

Reservoir Temperature=213F

Standard Pressure=15.025 psia

Standard Temperature=60F

Cumulative production= 1.00 x 10

9

SCF

Average reservoir pressure=2864 psia

Abandonment pressure = 500 psia

Gas deviation Factor at 3250 psia= 0.910

Gas deviation Factor at 2864 psia= 0.888

Gas deviation Factor at 500 psia = 0.951

STEP-1

Calculate reservoir gas pore volume V

i

(using cum gas/

production and pressure details)

{( 15.025 x 1.00 x 10

9

x )/520}

= {(3250 x V

i

)/(0.910 x673)} {(2864 x V

i

)/(0.888 x

673)}

= 56.17 MM Cu ft

STEP-2

Calculate the initial gas in place G (at initial pressure)

G= (p

i

V

i

/ z

i

T ) x (T

sc

/ p

sc

) = (p

i

V

i

T

sc

/ z

i

T p

sc

)

=(3250 x 56.17 x 10

6

x 520) / (0.910 x 673 x 15.025)

= 10.32 MMM SCF

STEP 3

Calculate gas remaining at500psia (Aband. Pressure)

G

a

= (p

a

V

i

/ z

a

T ) x (T

sc

/ p

sc

)

=(500 x 56.17 x 10

6

x 520) / (0.951 x 673 x 15.025)

= 1.52 MMM SCF

As initial gas reserves based on a 500 psia

(Aband. Pressure) is the difference between

the initial gas in place and the gas remaining at

500 psia . Therefore gas reserve may be given

as

G

r

= G G

a

=

(10.32 1 52) x 10

9

= 8.80 MMM SCF

Example

Calculate the total daily gas production including the

water and condensate using the given data:

Daily separator Gas Production =3.25 MM SCF

Daily Stock Tank Condensate =53.2 STB

Daily Stock Tank Gas =10 M SCF

Daily Fresh Water Production =5.5 bbl*

Initial reservoir Pressure =4000 psia

Current Reservoir Pressure =1500 psia

Reservoir Temperature =220 F

Condensate Gravity = 55 API

(0.759 sp.gr.)

Use the Mol. Wt.(M

o

) as 124 also Consider only 40%

water as Produced water.

(only 60% water need to be converted to gas equivalent)

solution

1

Gas Equivalent = 53.2 x 133000 x 0.759/124

= 43,000 SCF

2

Gas Equivalent (water)= 3.25 x 7390

= 24000 SCF

3

Daily Stock tank gas = 10 M SCF

The Daily Gas Production ( G

P

)

G

P = 3250.0 M +10.0 M + 43.0 M + 24.0 M

= 3.327 MM SCF

If the standard conditions are 14.7 psia and 520R and the gas

constant,R,10.73:then the gas equivalent for water produced as

condensate is: 7390 scf/stb of water

Daily Stock Tank Condensate =53.2 STB(Given)

You might also like

- FinalDocument54 pagesFinallikpata100% (1)

- XxxscribdDocument5 pagesXxxscribdXavier ChimaemeNo ratings yet

- Gas Cap Oil ReservoirDocument10 pagesGas Cap Oil ReservoirJoseph YepezNo ratings yet

- Chapter 3 Wet-Gas ReservoirDocument22 pagesChapter 3 Wet-Gas ReservoirMohammed Bahram100% (1)

- Chapter 3 PDFDocument21 pagesChapter 3 PDFjeedNo ratings yet

- Choke Performance PDFDocument22 pagesChoke Performance PDFMuhammad ShehryarNo ratings yet

- Assignment 2 MBEDocument3 pagesAssignment 2 MBEBadut SarkasNo ratings yet

- ESP Design Hand CalculationsDocument17 pagesESP Design Hand CalculationsMuhammad ImranNo ratings yet

- Chapter 3 Wet-Gas ReservoirDocument22 pagesChapter 3 Wet-Gas ReservoirMohammed BahramNo ratings yet

- Reserve Estimation Methods 02 VolumetricDocument8 pagesReserve Estimation Methods 02 VolumetricsiriuslotNo ratings yet

- Gas Condensate ReservoirDocument33 pagesGas Condensate ReservoirMohammad Iqbal Mahamad Amir100% (3)

- ESP Design - Hand Calculations: Step 1: Basic DataDocument16 pagesESP Design - Hand Calculations: Step 1: Basic DataAlamen GandelaNo ratings yet

- Volumetric CalculationsDocument9 pagesVolumetric CalculationsFuad MohamedNo ratings yet

- Ex 1Document2 pagesEx 1JAY BNo ratings yet

- Chapter 2 Classification, Types and Dry-Gas ReservoirDocument40 pagesChapter 2 Classification, Types and Dry-Gas ReservoirMohammed BahramNo ratings yet

- ESP 9 Steps Design Hand CalculationsDocument16 pagesESP 9 Steps Design Hand CalculationsMohamed GhareebNo ratings yet

- 1 - Introduction To Nodal AnalysisDocument35 pages1 - Introduction To Nodal AnalysisLuis Marcio AvendañoNo ratings yet

- Chapter 2 PDFDocument39 pagesChapter 2 PDFjeedNo ratings yet

- TM 3110 Ujian-Tengah-Semester 2021 15 Oktober 2021Document5 pagesTM 3110 Ujian-Tengah-Semester 2021 15 Oktober 2021TM143Adam Putra Pratama ZainuriNo ratings yet

- PTE 526 Natural Gas Engineering: BY Engr. J. O. OwolabiDocument124 pagesPTE 526 Natural Gas Engineering: BY Engr. J. O. Owolabiokeke ekeneNo ratings yet

- Example Problem On Determination of Point of Gas InjectionDocument2 pagesExample Problem On Determination of Point of Gas InjectionrehmanNo ratings yet

- REN5415 - Y19 - Lec13, 14 &15Document87 pagesREN5415 - Y19 - Lec13, 14 &15Abdulla MohammadNo ratings yet

- Gas SolubilityDocument59 pagesGas SolubilityAustine Ameh0% (1)

- Wet Gas ReservoirsDocument25 pagesWet Gas ReservoirsMohammed Khaled Al-ThobhaniNo ratings yet

- Problem Bo RateBig PDFDocument12 pagesProblem Bo RateBig PDFStewart DavidNo ratings yet

- ENPE 302 Applied Reservoir Engineering Date: Jan. 15, 2013 Due: Jan. 31, 2012 Homework # 2Document2 pagesENPE 302 Applied Reservoir Engineering Date: Jan. 15, 2013 Due: Jan. 31, 2012 Homework # 2lanley3No ratings yet

- Chapter 4 Gas Condensate ReservoirsDocument34 pagesChapter 4 Gas Condensate ReservoirsMohammed Bahram100% (1)

- Problems Cap3Document5 pagesProblems Cap3Sharon Osorio Calderon0% (1)

- Reservoir Development PlanDocument14 pagesReservoir Development PlanOtitolaiye Olamide TNo ratings yet

- Tutorial 2 EORDocument23 pagesTutorial 2 EORAhmed FaragallahNo ratings yet

- MbeDocument6 pagesMbeMarco PlaysNo ratings yet

- 3.1 Gas Field Dev Exercise QuestionsDocument3 pages3.1 Gas Field Dev Exercise Questionsgilberto monteiroNo ratings yet

- PVT AnalysisDocument40 pagesPVT AnalysisBrian CbtngnNo ratings yet

- HW5 SolutionDocument6 pagesHW5 SolutionMohammad Iqbal Mahamad Amir85% (20)

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Ex 2Document1 pageEx 2Amir MNo ratings yet

- Unassigned Problem - 25 - SolutionsDocument7 pagesUnassigned Problem - 25 - Solutionsธนลักษณ์ งามปัญจะNo ratings yet

- Reservoir-Fluid Property CorrelationsDocument8 pagesReservoir-Fluid Property Correlationscapl930No ratings yet

- 1.4quantitative Use of PorosityDocument18 pages1.4quantitative Use of Porosityhamza alqadasiNo ratings yet

- HW5Document2 pagesHW5Mohammad Iqbal Mahamad Amir100% (1)

- Pe 04025 ReservoirDocument11 pagesPe 04025 ReservoirSona SithNo ratings yet

- Yussuf Crude Stabilization TaskDocument4 pagesYussuf Crude Stabilization TaskYussuf AbassNo ratings yet

- Assigement 1 Pete OlmecaDocument2 pagesAssigement 1 Pete OlmecaleeNo ratings yet

- Reservoir Engineering Lecture Notes: G.C.EnyiDocument39 pagesReservoir Engineering Lecture Notes: G.C.EnyiRaimundoNo ratings yet

- 1Document6 pages1shivam aggarwalNo ratings yet

- Ali Abukhzam - HW1&2Document4 pagesAli Abukhzam - HW1&2Ali AbukhzamNo ratings yet

- Group 3: Bismark Oteng 403 Dickson Udebhulu Oh Ikiria Anthony Agbauduta Elizabeth Akonobea A PpiahDocument10 pagesGroup 3: Bismark Oteng 403 Dickson Udebhulu Oh Ikiria Anthony Agbauduta Elizabeth Akonobea A PpiahlikpataNo ratings yet

- Fluid Properties - Comprehensive Formation Volume Factor ModuleDocument46 pagesFluid Properties - Comprehensive Formation Volume Factor ModuleIbrahim_Kocabas100% (10)

- Faculty of Engineering and Technology Department of Petroleum EngineeringDocument9 pagesFaculty of Engineering and Technology Department of Petroleum EngineeringCharryann Tiffany WilliamsNo ratings yet

- Assignment Group No 4Document33 pagesAssignment Group No 4Alhaj MassoudNo ratings yet

- 8echapter02 SMDocument115 pages8echapter02 SMAnonymous mXicTi8hBNo ratings yet

- PETE 625 Well Control: Lesson 4 Gas SolubilityDocument59 pagesPETE 625 Well Control: Lesson 4 Gas SolubilityDavid ReyesNo ratings yet

- Assignment-1 PEEM 3203Document5 pagesAssignment-1 PEEM 3203Yawe DominicNo ratings yet

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- Profit Loss Report 367436 20203908093927 PDFDocument3 pagesProfit Loss Report 367436 20203908093927 PDFAbhinav GoyalNo ratings yet

- 50 PDFDocument1 page50 PDFAbhinav GoyalNo ratings yet

- Iadc WW Surfacestack Field 012214Document3 pagesIadc WW Surfacestack Field 012214DirafNo ratings yet

- This Is A Manual of Drilling Technical ManualDocument1 pageThis Is A Manual of Drilling Technical ManualAbhinav GoyalNo ratings yet

- Well Summary Data: Includes Shared Rig Move TimeDocument1 pageWell Summary Data: Includes Shared Rig Move TimeAbhinav GoyalNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- Annular VelocityDocument1 pageAnnular VelocityAbhinav GoyalNo ratings yet

- ImpdocDocument1 pageImpdocAbhinav GoyalNo ratings yet

- CompanyDocument1 pageCompanyAbhinav GoyalNo ratings yet

- Case DrillDocument1 pageCase DrillAbhinav GoyalNo ratings yet

- Well Stimulation - Hydraulic FracturingDocument3 pagesWell Stimulation - Hydraulic FracturingAbhinav GoyalNo ratings yet

- Well PlanDocument1 pageWell PlanAbhinav GoyalNo ratings yet

- Goodafternoon One N AllDocument3 pagesGoodafternoon One N AllAbhinav GoyalNo ratings yet

- Its CaseDocument1 pageIts CaseAbhinav GoyalNo ratings yet

- ExercisesDocument6 pagesExercisesAbhinav GoyalNo ratings yet

- Analysis of Cost EstimationDocument58 pagesAnalysis of Cost Estimationccsreddy100% (3)

- MotorDocument20 pagesMotortechzonesNo ratings yet

- This Minor Makes You Fool HohohoDocument1 pageThis Minor Makes You Fool HohohoAbhinav GoyalNo ratings yet

- WrteDocument1 pageWrteAbhinav GoyalNo ratings yet

- LoklDocument1 pageLoklAbhinav GoyalNo ratings yet

- This O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaDocument1 pageThis O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaAbhinav GoyalNo ratings yet

- Document ImpDocument1 pageDocument ImpAbhinav GoyalNo ratings yet

- MAOP UpratingDocument32 pagesMAOP UpratingAbhinav GoyalNo ratings yet

- Chapter 5 - Drill BitDocument18 pagesChapter 5 - Drill BitAbhinav Goyal100% (1)

- Acuprressurefundamentals PDFDocument25 pagesAcuprressurefundamentals PDFBosko Ljubisavljevic88% (8)

- B.tech MidsemoctDocument8 pagesB.tech MidsemoctAbhinav GoyalNo ratings yet

- CoatingDocument8 pagesCoatingAbhinav GoyalNo ratings yet

- Pipeline ConstructionDocument19 pagesPipeline ConstructionJose Anisio SilvaNo ratings yet

- Well Control ReportDocument3 pagesWell Control ReportAbhinav GoyalNo ratings yet

- Recovery MethodsDocument90 pagesRecovery MethodsmustafaNo ratings yet

- Ielts Writing Task 1Document63 pagesIelts Writing Task 1tinhmaixatoi2006100% (1)

- Sentence Rearrangement For SBI Clerk Prelims: Get High Standard Mock Test Series For All Bank ExamsDocument11 pagesSentence Rearrangement For SBI Clerk Prelims: Get High Standard Mock Test Series For All Bank ExamsRajkumar SirNo ratings yet

- FPSO Sangomar External Turret: Sangom Ar Field - SenagalDocument1 pageFPSO Sangomar External Turret: Sangom Ar Field - SenagalDanish KhandelwalNo ratings yet

- Differential Liberation Test Experiment No.2.: University of Zakho Collage of Engineering Petroleum DepartmentDocument15 pagesDifferential Liberation Test Experiment No.2.: University of Zakho Collage of Engineering Petroleum DepartmentSoma BerwariNo ratings yet

- DammerDocument31 pagesDammer김도연No ratings yet

- Full ThesisDocument87 pagesFull Thesishasan noahNo ratings yet

- OSV Inspection BookDocument44 pagesOSV Inspection BookMohamed HassanNo ratings yet

- BA108DEN Promass 83 Modbus Rs485 DDDocument190 pagesBA108DEN Promass 83 Modbus Rs485 DDyuvionfireNo ratings yet

- Section 22 - MCII Flow AnalyserDocument19 pagesSection 22 - MCII Flow AnalyserhammamiNo ratings yet

- Earnings Report - 1Q23Document27 pagesEarnings Report - 1Q23Iasmin Rao PaivaNo ratings yet

- Engineering Units ConverterDocument23 pagesEngineering Units ConverterknsaravanaNo ratings yet

- Venting of Atmospheric and Low Pressure Storage TanksDocument8 pagesVenting of Atmospheric and Low Pressure Storage TanksArun SankarNo ratings yet

- Nang Nuan Oil Field, Gulf of Thailand - Karst Reservoirs of Metoric or Deep-Burial OriginDocument13 pagesNang Nuan Oil Field, Gulf of Thailand - Karst Reservoirs of Metoric or Deep-Burial OriginHenrickson MouraNo ratings yet

- Karurkar 2015Document12 pagesKarurkar 2015HSEQ AZUL ENERGYNo ratings yet

- PillsDocument3 pagesPillsAhmedMohsenNo ratings yet

- SPE-180776-MS Slug Flow Regime and Mitigation Using Transient Simulation, A Complete WorkflowDocument14 pagesSPE-180776-MS Slug Flow Regime and Mitigation Using Transient Simulation, A Complete WorkflowAnonymous 8te2h1No ratings yet

- iGCSEPakistan20Studies20 (0448) 20200448 w20 QP 02 PDFDocument24 pagesiGCSEPakistan20Studies20 (0448) 20200448 w20 QP 02 PDFAsad PashaNo ratings yet

- Differential Liberation - LabDocument12 pagesDifferential Liberation - LabAhmed AmirNo ratings yet

- 10 - Simple Mud Engineerv1.22Document22 pages10 - Simple Mud Engineerv1.22Abdul Hameed OmarNo ratings yet

- AR 2015 SaudiAramco English FullDocument104 pagesAR 2015 SaudiAramco English Fullxtrooz abiNo ratings yet

- A PRESENTATION On Modular Mini Refinery Project PDFDocument28 pagesA PRESENTATION On Modular Mini Refinery Project PDFrashidulNo ratings yet

- Chevron 2013 10KDocument122 pagesChevron 2013 10Knant4618967No ratings yet

- Fortis Webinar April 2010Document41 pagesFortis Webinar April 2010ahelios79No ratings yet

- PngstatDocument177 pagesPngstatNitesh ChauhanNo ratings yet

- Origin of PetroeumDocument75 pagesOrigin of PetroeumOliverQueenNo ratings yet

- Assignment For MBA BADocument2 pagesAssignment For MBA BAsrishti kharbandaNo ratings yet

- Niger Delta GeologyDocument24 pagesNiger Delta Geologysamuel100% (1)