Professional Documents

Culture Documents

Power System Operations

Uploaded by

Angelo Mark Ordoña PorgatorioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power System Operations

Uploaded by

Angelo Mark Ordoña PorgatorioCopyright:

Available Formats

EE 425

POWER SYSTEM OPERATION

NOVEMBER 2012

ENGR. D. ALPIS

POWER SYSTEM OPERATION

POWER PLANT

A power station or power plant is a facility for the generation of electric power. 'Power plant' is also used to refer to the engine in ships, aircraft and other large vehicles. Some prefer to use the term energy center because it is more accurately describes what the plants do, which is the conversion of other forms of energy, like chemical energy, gravitational potential energy or heat energy into electrical energy.

POWER SYSTEM OPERATION

POWER PLANT

At the center of nearly all power stations is a generator, a rotating machine that converts mechanical energy into electrical energy by creating relative motion between a magnetic field and a conductor. The energy source harnessed to turn the generator varies widely. It depends chiefly on what fuels are easily available and the types of technology that the power company has access to.

POWER SYSTEM OPERATION

POWER PLANT ENGINEERING

Art of designing and installing generating plant that will result in maximum return on investment (profit) over the expected life of the equipment. And also operating this equipment to achieve reliable, continuous and cheap power service. POWER PLANT ENGINEERING A station or establishment which houses the prime-movers, electric generators and auxiliaries, for conversion of mechanical, chemical and/ or nuclear energy into electrical energy.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

1. By FUEL a. NUCLEAR POWER PLANTS use a nuclear reactors heat to operate a steam turbine generator.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

b. FOSSIL FUEL POWERED PLANTS may also used a steam turbine generator or a NATURAL GAS fired plants may use a combustion turbine.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

c. GEOTHERMAL POWER PLANTS uses steam extracted from hot underground rocks.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

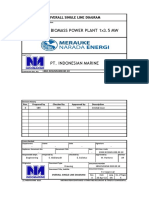

d. RENEWABLE ENERGY PLANTS maybe fuelled by waste from sugar cane, municipal solid waste, landfill or methane or other forms of Biomass. 2. By PRIME MOVER

a. STEAM TURBINE plants use the pressure generated by expanding steam to turn the blades of a turbine. b. GAS TURBINE plants use the heat from gases to directly operate the turbine. Natural gas fuelled turbine plants can start rapidly and so are used to supply "peak" energy during periods of high demand, though at higher cost than base-loaded plants.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

c. COMBINED CYCLE plants have both a gas turbine fired by natural gas, and a steam boiler and steam turbine which use the exhaust gas from the gas turbine to produce electricity. This greatly increases the overall efficiency of the plant, and most new base-load power plants are combined cycle plants fired by natural gas.

d. Internal combustion Reciprocating Engines are used to provide power for isolated communities and are frequently used for small co-generation plants. Hospitals, office buildings, industrial plants, and other critical facilities also use them to provide backup power in case of a power outage. These are usually fuelled by diesel oil, heavy oil, natural gas and landfill gas.

POWER SYSTEM OPERATION

THERMAL POWER PLANT CLASSIFICATION

e. MICROTURBINES, STIRLING ENGINES and internal combustion reciprocating engines are low cost solutions for using opportunity fuels, such as landfill gas, digester gas from water treatment plants and waste gas from oil production.

POWER SYSTEM OPERATION

OTHER SOURCES OF ENERGY

Other power stations use the energy from wave or tidal motion, wind, sunlight or the energy of falling water, hydroelectricity. These types of energy sources are called renewable energy. Hydro Electric Power Plant an electric generating station using flowing waters to drive the prime-movers (hydraulic turbines) either impulse or reaction type.

POWER SYSTEM OPERATION

TWO TYPES OF HYDRAULIC TURBINES a) Impulse Type use for high-heads and low volume, example is the Pelton wheel. b) Reaction Type use for low-heads and high volume, examples are Francis and Kaplan.

TYPES OF HYDRO-ELECTRIC PLANT

a) Run-of-river using pondage or steam flow as it occurs, more power can be generated in a rainy season than in dry season. b) Plant with storage capacity associated with a large water reservoir. This permits regulated supply of water so that the power output is constant throughout the year.

POWER SYSTEM OPERATION

TYPES OF HYDRO-ELECTRIC PLANT

c) Pump-storage Plant where energy is generated during periods of high system demand using water which has been pumped into a reservoir usually during periods of relatively low system demands.

3. Diesel Power Plant a plant of internal combustion engine (ICE) prime-mover using diesel as fuel in producing energy. 4. Windmill Plant using a series of windmills as prime-mover.

POWER SYSTEM OPERATION

OTHER SOURCES OF ENERGY

5. Sea waves / Ocean Tides Plant makes use of the natural rising of tide to simulate flowing water. 6. Solar or Photo-Voltaic Plant chemical conversion of radiant energy of the sun to electric (dc) energy.

POWER SYSTEM OPERATION

Types of Power Plant (As to Use)

1. Base-Load Plant plant that assumed load requirements under normal conditions. 2. Peaking Plant plant that is normally operated to provide power only during peak load periods.

3. Regulating Plant plant capable of carrying load for the time interval either during off-peak or peak periods and usually responds to changes in system frequency.

4. Reserve or Stand by Plant for peak or system deficiencies.

POWER SYSTEM OPERATION

TYPES OF PLANT RESERVES

a) Cold Reserve portion of the installed reserve kept in operable condition and available for service but not for immediate loading. b) Operating Reserve refers to capacity in actual service in excess of peak loads. c) Hot reserve refers to units available, maintained at operating temperature and ready for service although not in actual operation. d) Spinning Reserve generating capacity connected to the bus ready to take load.

POWER SYSTEM OPERATION

THERMAL EFFICIENCY (et)

e = Heat equivalent of mechanical energy transmitted to the turbine Heat of fuel combustion

Wnet Q A - QR QR Tcold = = = 1= 1QA QA QA Thot

where : Wnet = Wt - WP

Overall Efficiency (eo)

Heat Equivalent of Electrical Output = Heat of Fuel Combustion

POWER SYSTEM OPERATION

THERMAL EFFICIENCY (et)

= e t x eg

where : e g = electrical efficiency = alternator efficiency

HEAT RATE (HR)

HR =

xK

where : K = constant conversation factor

Values of K based from the following Conversion Factor

1 KWh = 3600 KJ 1 HP hr = 2545 BTU 1 kWh = 3413 BTU 1 KWh = 860 Kcal.

POWER SYSTEM OPERATION

IMPORTANT TERMS AND PLANT FACTORS:

1. Connected Load (CL) it is the sum of all continuous rating of all utilization equipment in the consumer premises connected to the supply system. 2. Maximum Demand (or Peak Load) (MD) it is the greatest demand of load on the power station during a given period. 3. Average Load (AL) the average of loads occurring on the power station in a given period, sometimes called average demand.

Total Energy Produced TEP Average Load AL = Period

POWER SYSTEM OPERATION

IMPORTANT TERMS AND PLANT FACTORS:

4. Demand Factor (DF) it is the ratio of maximum demand on the power station to its connected load.

Demand Factor DF = MD 1.0 CL

5. Diversity Factor (Div F) the ratio of the sum of individual maximum demand to the simultaneous maximum demand on the power station.

Div. Factor DF =

MD's 1.0 simulataneous MD

POWER SYSTEM OPERATION

IMPORTANT TERMS AND PLANT FACTORS:

6. Coincidence Factor (CO. F) reciprocal of diversity factor.

1 Co. Factor Co.F = simulataneous MD = 1.0 MD's Div. Factor

7.Load Factor (LF) it is the ratio of average load to the maximum demand during a given period.

L.F. =

Average Load = TEP MaximumDemand M.D. x Sr

POWER SYSTEM OPERATION

IMPORTANT TERMS AND PLANT FACTORS:

8.Capacity Factor (CF) it is the ratio of actual energy produced to the maximum possible energy that could have been produced during a given period.

C.F. = TEP I.C. x P r

9.Nameplate or Capacity Rating is the ability to carry load under conditions specify by the manufacturer.

10. Capability Rating is the maximum output of equipment obtained by test under specific operating condition (not specified by manufacturer)

POWER SYSTEM OPERATION

IMPORTANT TERMS AND PLANT FACTORS:

11. Plant Use (or Output) Factor it is the ratio of the energy generated to the product of plant capacity and the number of hours for which the plant was in operation.

P.U.F =

TEP I.C. x Sr

You might also like

- Basic Electrical Power Fundamentals PDFDocument6 pagesBasic Electrical Power Fundamentals PDFAnthony MucciNo ratings yet

- Nptel 1Document57 pagesNptel 1Lanku J GowdaNo ratings yet

- Tariff Determination - Write UpDocument12 pagesTariff Determination - Write UpnikhilkrsinhaNo ratings yet

- 4 Wiring Calculations & Specifications For Single Family Dwelling Unit (With Updated Tables)Document47 pages4 Wiring Calculations & Specifications For Single Family Dwelling Unit (With Updated Tables)EdryanPoNo ratings yet

- Power System Analysis - Hadi Saadat (Chapter 4)Document41 pagesPower System Analysis - Hadi Saadat (Chapter 4)TsalachNo ratings yet

- Electrical Manual 50KDocument376 pagesElectrical Manual 50Ksunil katiyarNo ratings yet

- Module 4 Feedback and Control SystemDocument2 pagesModule 4 Feedback and Control SystemRayJay BilgeraNo ratings yet

- Calculating The Shortcircuit Current Across The Terminals of A Synchronous GeneratorDocument2 pagesCalculating The Shortcircuit Current Across The Terminals of A Synchronous GeneratorRobert GalarzaNo ratings yet

- Power Plant Engg.Document2 pagesPower Plant Engg.akr324735No ratings yet

- Familiarisation of PP-3 Power PlantsDocument11 pagesFamiliarisation of PP-3 Power PlantsPushpendra Mishra100% (1)

- Easy Understanding 3phase Transformer ConnectionsDocument6 pagesEasy Understanding 3phase Transformer ConnectionsMateo BastidasNo ratings yet

- Availability Based Tariff Gyanendra Sharma NPTI DelhiDocument82 pagesAvailability Based Tariff Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Generator ExcitationDocument5 pagesGenerator ExcitationPritam SinghNo ratings yet

- Large Generator Course InfoDocument8 pagesLarge Generator Course Inforosario.md1052No ratings yet

- GE Suit Against UptakeDocument41 pagesGE Suit Against UptakeAnonymous 6f8RIS6100% (2)

- Project in Ieee FormatDocument4 pagesProject in Ieee FormatShashwat SinghNo ratings yet

- Ohms Law Formulas PDFDocument5 pagesOhms Law Formulas PDFAnonymous P1r2fMJ9No ratings yet

- Generating StationsDocument49 pagesGenerating StationsZafar Ali KhanNo ratings yet

- IIEE-NCC GMM - Power Quality - VFPelagoDocument56 pagesIIEE-NCC GMM - Power Quality - VFPelagoJellyn BaseNo ratings yet

- 4 Main Types of Distribution Feeder Systems To Recognize - EEPDocument11 pages4 Main Types of Distribution Feeder Systems To Recognize - EEPFernando CastroNo ratings yet

- Underground Distribution SystemDocument129 pagesUnderground Distribution SystemjporangecubeNo ratings yet

- Various Plants used for Electric Power Generation: Hydro, Nuclear & ThermalDocument6 pagesVarious Plants used for Electric Power Generation: Hydro, Nuclear & ThermalWilson FuentesNo ratings yet

- Exhaust Fan CatalogDocument32 pagesExhaust Fan Catalogcumpio425428No ratings yet

- AC Apparatus and Devices Activity 1 1Document1 pageAC Apparatus and Devices Activity 1 1benny bullNo ratings yet

- Blackout RestorationDocument26 pagesBlackout RestorationSiddhant SatpathyNo ratings yet

- Overall Single Line DiagramDocument6 pagesOverall Single Line DiagramAdith Wiendar P PutraNo ratings yet

- Polyphase RectifierDocument4 pagesPolyphase RectifierGlenda Grageda100% (1)

- MCQ in AC Circuits Part 1 REE Board ExamDocument18 pagesMCQ in AC Circuits Part 1 REE Board ExamRogelio Jr. Dela CruzNo ratings yet

- Power System First (WWW - Allexamreview.Document108 pagesPower System First (WWW - Allexamreview.manivithNo ratings yet

- Documents - Pub Training Report 565de94aa5c26Document47 pagesDocuments - Pub Training Report 565de94aa5c26EE OPN1TTPSNo ratings yet

- Power System EconomicsDocument378 pagesPower System Economicsmazinkaiser217450% (2)

- Ramachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELDocument34 pagesRamachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELraspberry piNo ratings yet

- Analysis of Power System StabilityDocument31 pagesAnalysis of Power System Stabilitytarnedo1100% (1)

- Power PlantDocument1 pagePower PlantSahi NagarajanNo ratings yet

- Basler Transformer Protection Application Guide PDFDocument33 pagesBasler Transformer Protection Application Guide PDFAbrakain69No ratings yet

- Protection System Fundamentals 060210Document55 pagesProtection System Fundamentals 060210Vivek SinghNo ratings yet

- Varun Singh - (2006-2010) .EE... BHEL HaridwarDocument77 pagesVarun Singh - (2006-2010) .EE... BHEL Haridwarvaruns1nghNo ratings yet

- Accounting and Its Relationship To Engineering EconomyDocument53 pagesAccounting and Its Relationship To Engineering Economymacmolles2380% (5)

- Stability AnalysisDocument17 pagesStability AnalysisSandeepReddyGoluguriNo ratings yet

- Report on Field Visit to Sojitz Kelanitissa Power StationDocument12 pagesReport on Field Visit to Sojitz Kelanitissa Power Stationkavish malakaNo ratings yet

- Annex "A-1"Document18 pagesAnnex "A-1"Earl IneNo ratings yet

- Statics 13esi Solutions-Manual Chapter 10Document63 pagesStatics 13esi Solutions-Manual Chapter 10Kavinesh AnanthanNo ratings yet

- Interest and Depreciation For Electrical Power GenerationDocument7 pagesInterest and Depreciation For Electrical Power GenerationKopi Brisbane100% (1)

- Resolving Software Issues PscadDocument62 pagesResolving Software Issues PscadGökhanDuru0% (1)

- Evaluation Condition of Transformer Based On Infrared Thermography ResultsDocument4 pagesEvaluation Condition of Transformer Based On Infrared Thermography Resultscarlos patrickNo ratings yet

- Sadelmi Power: List of ReferencesDocument24 pagesSadelmi Power: List of ReferencesBoulos NassarNo ratings yet

- Orca Share Media1591704590140 PDFDocument58 pagesOrca Share Media1591704590140 PDFEdrielle ValdezNo ratings yet

- Experiment 1 Nitesh Hatankar (I-48) Title: Objective: AbstractDocument5 pagesExperiment 1 Nitesh Hatankar (I-48) Title: Objective: AbstractKkNo ratings yet

- Ee 34 Fundamentals of Power Plant Engineering DesignDocument34 pagesEe 34 Fundamentals of Power Plant Engineering Designjeraldogong2No ratings yet

- Powergeneration 190508075320Document19 pagesPowergeneration 190508075320SRINIVAS TNo ratings yet

- Ppe Notes LatestDocument95 pagesPpe Notes LatestBADINEHALSANDEEPNo ratings yet

- Thermal Power Plants: By: Ahmad AbuhusseinDocument35 pagesThermal Power Plants: By: Ahmad AbuhusseinRaed IzzatNo ratings yet

- Factors for installing a 5 MW solar PV power plantDocument94 pagesFactors for installing a 5 MW solar PV power plantDeepakNo ratings yet

- Summer Training Report: Amit Kumar Verma ECE (6th Sem)Document26 pagesSummer Training Report: Amit Kumar Verma ECE (6th Sem)Sukriti JainNo ratings yet

- Power Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeDocument14 pagesPower Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeAt Sa Wakas AyNo ratings yet

- Mani Report 1Document53 pagesMani Report 1Mani MukatiNo ratings yet

- Lecture 9 Hydroelectric Power PlantsDocument32 pagesLecture 9 Hydroelectric Power PlantsCasuncad GilbertNo ratings yet

- Study Report 0002Document10 pagesStudy Report 0002kjfensNo ratings yet

- Types of Distributed Energy ResourcesDocument13 pagesTypes of Distributed Energy ResourceschaitanyadathNo ratings yet

- COM100D/COM100E Smart Communication Box User ManualDocument42 pagesCOM100D/COM100E Smart Communication Box User ManualrolandogaraysalazarNo ratings yet

- SeemeDocument1 pageSeemeAngelo Mark Ordoña PorgatorioNo ratings yet

- Greater China: Offices in AsiaDocument2 pagesGreater China: Offices in AsiaAngelo Mark Ordoña PorgatorioNo ratings yet

- Solar Operations and Maintenance: 550 KW CF Aguilar Rice MillDocument27 pagesSolar Operations and Maintenance: 550 KW CF Aguilar Rice MillAngelo Mark Ordoña PorgatorioNo ratings yet

- LemonDocument1 pageLemonAngelo Mark Ordoña PorgatorioNo ratings yet

- BLK SIEDocument1 pageBLK SIEAngelo Mark Ordoña PorgatorioNo ratings yet

- SE Three PhaseDocument3 pagesSE Three PhaseAngelo Mark Ordoña PorgatorioNo ratings yet

- Hanwha Q CELLS Data Sheet QPEAK DUO-G5 315-330 2017-07 Rev01 EN PDFDocument2 pagesHanwha Q CELLS Data Sheet QPEAK DUO-G5 315-330 2017-07 Rev01 EN PDFDumitru GigiNo ratings yet

- 14 Commissioning Maintenance and TroubleshootingDocument50 pages14 Commissioning Maintenance and TroubleshootingAlan B100% (2)

- VandaDocument1 pageVandaAngelo Mark Ordoña PorgatorioNo ratings yet

- DIY Bike Rack Assembly DiagramDocument1 pageDIY Bike Rack Assembly DiagramAngelo Mark Ordoña PorgatorioNo ratings yet

- Scan Doc by CamScannerDocument1 pageScan Doc by CamScannerAngelo Mark Ordoña PorgatorioNo ratings yet

- Iso BracketDocument1 pageIso BracketAngelo Mark Ordoña PorgatorioNo ratings yet

- EaDocument1 pageEaAngelo Mark Ordoña PorgatorioNo ratings yet

- TexDocument1 pageTexAngelo Mark Ordoña PorgatorioNo ratings yet

- SeetDocument1 pageSeetAngelo Mark Ordoña PorgatorioNo ratings yet

- Employee payroll report for Angelo Mark PorgatorioDocument2 pagesEmployee payroll report for Angelo Mark PorgatorioAngelo Mark Ordoña PorgatorioNo ratings yet

- Canbas PDFDocument1 pageCanbas PDFAngelo Mark Ordoña PorgatorioNo ratings yet

- Employee payroll report for Angelo Mark PorgatorioDocument2 pagesEmployee payroll report for Angelo Mark PorgatorioAngelo Mark Ordoña PorgatorioNo ratings yet

- OSEIA Solar Safety 12-06Document112 pagesOSEIA Solar Safety 12-06srujanyeleti100% (1)

- Daily Time RecordDocument2 pagesDaily Time RecordCarlo Fernando PadinNo ratings yet

- Canbas PDFDocument1 pageCanbas PDFAngelo Mark Ordoña PorgatorioNo ratings yet

- 001 2020 2 MonDocument16 pages001 2020 2 MonAngelo Mark Ordoña PorgatorioNo ratings yet

- Emailing Request - SMA Exchange Device Form - MPS PDFDocument1 pageEmailing Request - SMA Exchange Device Form - MPS PDFAngelo Mark Ordoña PorgatorioNo ratings yet

- Book 6 of 8Document1 pageBook 6 of 8Angelo Mark Ordoña PorgatorioNo ratings yet

- Salmo 15456Document1 pageSalmo 15456Angelo Mark Ordoña PorgatorioNo ratings yet

- RubbaDocument1 pageRubbaAngelo Mark Ordoña PorgatorioNo ratings yet

- O71WDocument1 pageO71WAngelo Mark Ordoña PorgatorioNo ratings yet

- One FriesDocument1 pageOne FriesAngelo Mark Ordoña PorgatorioNo ratings yet

- VcoDocument1 pageVcoAngelo Mark Ordoña PorgatorioNo ratings yet

- 8th GasTurbines ConfDocument5 pages8th GasTurbines ConfSyedNadeemAhmedNo ratings yet

- Numerical Study of Six Bladed Savonius Wind TurbineDocument5 pagesNumerical Study of Six Bladed Savonius Wind TurbineShashank Mishra100% (1)

- 1 s2.0 S187661021735453X Main PDFDocument6 pages1 s2.0 S187661021735453X Main PDFDexter Asprin DulayNo ratings yet

- GE 9FB Gas Turbine Maintenance OverviewDocument10 pagesGE 9FB Gas Turbine Maintenance Overviewgalinalbertas100% (1)

- Turbo Air VentilatorsDocument13 pagesTurbo Air VentilatorsmishrasujitNo ratings yet

- Chapter 71 - Power Plant: BHT-206L4-MM-9Document54 pagesChapter 71 - Power Plant: BHT-206L4-MM-9Raisa RabeyaNo ratings yet

- Review: Turbine and Related Flowmeters: !. Industrial PracticeDocument15 pagesReview: Turbine and Related Flowmeters: !. Industrial PracticemohmehrNo ratings yet

- Wind TurbineDocument23 pagesWind TurbineTekko JaraNo ratings yet

- Kirsch 2009 MainProjectDocument118 pagesKirsch 2009 MainProjectanand sahuNo ratings yet

- TCLDocument198 pagesTCLVaisakVenugopal100% (1)

- CM20150703 52095 19102 PDFDocument2 pagesCM20150703 52095 19102 PDFsudhindra_tiwariNo ratings yet

- Mechanical Engineering Department ME 47 (ME Final Year Project Study 1)Document20 pagesMechanical Engineering Department ME 47 (ME Final Year Project Study 1)Roy RagotNo ratings yet

- Recnik Mesovitih Tehnickih PojmovaDocument74 pagesRecnik Mesovitih Tehnickih PojmovaSlaviša Šimetić60% (5)

- MEM - Project Pump and TurbineDocument22 pagesMEM - Project Pump and TurbineAbhi ChavanNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Model Tests For Offshore Wind Tur-BinesDocument19 pagesITTC - Recommended Procedures and Guidelines: Model Tests For Offshore Wind Tur-BinesLawrd RrafieNo ratings yet

- Turbine Blade Profile - Bezier CurvesDocument10 pagesTurbine Blade Profile - Bezier Curvesvarun gopiNo ratings yet

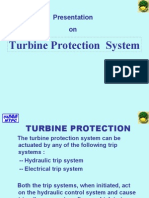

- 5 Turbine ProtectionDocument14 pages5 Turbine ProtectionSam100% (4)

- Design and Construction of Vertical Axis Wind TurbineDocument8 pagesDesign and Construction of Vertical Axis Wind TurbineRafat KashoomNo ratings yet

- Determination of Vertical Axis Wind Turbines Optimal Configuration Through CFD SimulationsDocument5 pagesDetermination of Vertical Axis Wind Turbines Optimal Configuration Through CFD SimulationsIbrahim LopezNo ratings yet

- MS5002EDocument8 pagesMS5002EMatt AgonyaNo ratings yet

- Maglev Wind Mill ReportDocument24 pagesMaglev Wind Mill ReportBalu MahendarNo ratings yet

- Pitch Versus Stall Wind EnergyDocument3 pagesPitch Versus Stall Wind EnergyUmer AbbasNo ratings yet

- Wind Turbine Design ProjectDocument4 pagesWind Turbine Design ProjectPushpa Mohan RajNo ratings yet

- Pelton TurbineDocument4 pagesPelton TurbineHenDricky Magosi100% (1)

- Maglev Wind MillDocument33 pagesMaglev Wind Millritesh chauhanNo ratings yet

- TB Maintenance Concept PDFDocument16 pagesTB Maintenance Concept PDFhamedia83No ratings yet

- M. Tech. Turbo MachinesDocument15 pagesM. Tech. Turbo MachinesmaitraikNo ratings yet

- Single Aisle Technical Training Manual Maintenance Course - M35 Line Mechanics (CFM56-5B/ME) APUDocument208 pagesSingle Aisle Technical Training Manual Maintenance Course - M35 Line Mechanics (CFM56-5B/ME) APUgabriel100% (1)

- Integral Analysis of Flow (Applications On Energy Equation)Document6 pagesIntegral Analysis of Flow (Applications On Energy Equation)ABDELRHMAN ALINo ratings yet

- Governing Mechanism of Francis TurbineDocument3 pagesGoverning Mechanism of Francis TurbineJennifer0% (1)