Professional Documents

Culture Documents

Cutting Speeds and Feeds Guide for Drilling Operations

Uploaded by

rautsushant21Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cutting Speeds and Feeds Guide for Drilling Operations

Uploaded by

rautsushant21Copyright:

Available Formats

1

Cutting Speeds and

Feeds

Unit 41

2

Cutting Speeds and Feeds

Two important factors

Diameter and material of cutting tool

Type of material being cut

Speed of twist drill referred to as cutting speed,

surface speed or peripheral speed

Distance point on circumference of drill will travel

in 1 min

3

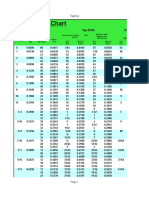

Recommended Cutting Speeds

Portion of Table 41.1 from text

Drill Size Cutting Speeds in Feet per Min or Meters per Min

in mm 40 ft/min 12 m/min 60 ft/min 18 m/min

1/16 2 2445 1910 3665 2865

1/8 3 1220 1275 1835 1910

3/16 4 815 955 1220 1430

Steel Casting Tool Steel

For every job, choose the drill speed that will

result in the best production rates!

4

Economical Drilling Speed

Variables

Type and hardness of material

Diameter and material of drill

Depth of hole

Type and condition of drill press

Efficiency of cutting fluid employed

Accuracy and quality of hole required

Rigidity of work setup

Most important!

5

Revolutions per Minute

Compute correct number of r/min of drill press

spindle for given size drill

Type of material to be drilled

Recommended cutting speed of material

Type of material from which drill is made

6

Formula (Inch)

inches) in nce circumfere (drill

12 minute) per feet (

min /

D

x CS

r

Revolution per minute = number of revolutions

of the drill necessary to attain proper cutting

speed for metal being machined.

where CS = recommended cutting speed in

feet per minute for the material being drilled

D = diameter of drill being used

7

Simplified Formula

Since not all machines can be set to exact calculated

speed, pi () divided into 12 to simplify formula

D

CS

r

4 x

min /

Example: Calculate r/min required to drill a in hole

in cast iron (CS 80) with a high-speed steel drill.

640

2 / 1

320

2 / 1

4 x 80

min / r

8

Formula (Metric)

) (

) (

min /

mm D

m CS

r

Convert so all units are in mm

D

CS

r

1000 x

min /

D

CS

r

320 x

min /

Example: Calculate r/min required to drill 15 mm hole in

tool steel (CS 18) using a high-speed steel drill.

384

15

5760

15

320 x 18

min / r

9

Feed

Distance drill advances into work for each

revolution

May be expressed in decimals, fractions of an

inch, or millimeters

Three factors govern rate of feed

Diameter of drill

Material of workpiece

Condition of drilling machine

10

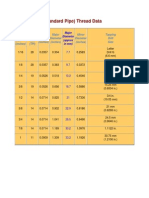

Drill Feeds

Table 41.2 Drill feeds

Drill Size Feed per Revolution

in. mm in. mm

18 and smaller 3 and smaller .001 to .002 0.02 to 0.05

18 to 3 to 6 .002 to .004 0.05 to 0.1

to 6 to 13 .004 to .007 0.1 to 0.18

to 1 13 to 25 .007 to .015 0.18 to 0.38

1 to 1 25 to 38 .015 to .025 0.38 to 0.63

General purpose Work

11

Drill Feeds

General rule: feed rate increases as drill size

increases

Too coarse chip cutting edges

Too light chattering noise, dulls cutting edge

Hard steels or alloys use slower feed

Softer metals drilled with faster feed

Blue steel chips indicate too much heat at cutting

edge

Dull cutting edge or too high speed

12

Cutting Fluids

Provide both cooling and lubrication

Properties of an effective liquid in dissipating

heat

Able to absorb heat rapidly

Have good resistance to evaporation

Have high thermal conductivity

Oil: good lubricant, poor coolant

Water: best coolant, no lubricating value (promotes rust)

13

Good Cutting Fluid

Cools workpiece and tool

Reduces friction

Improves cutting action

Protects work against rusting

Provides anti-weld properties

Washes away chips

You might also like

- 2010 MaxxForce DT-9-10 DiagnosticDocument1,329 pages2010 MaxxForce DT-9-10 Diagnosticbullfly100% (8)

- Trigonometry TablesDocument49 pagesTrigonometry Tablesdragos43No ratings yet

- Cutting Speeds & RPM CalculationsDocument7 pagesCutting Speeds & RPM Calculationsyanuar_adhiNo ratings yet

- Solutions To Irodov's Problems - Volume IIDocument442 pagesSolutions To Irodov's Problems - Volume IIZequinha de Abreu100% (2)

- Milling MachineDocument104 pagesMilling MachineMasud RanaNo ratings yet

- Dynamic model of manipulatorsDocument20 pagesDynamic model of manipulatorsbalkyderNo ratings yet

- Metrology & Workshop Practice ComponentsDocument48 pagesMetrology & Workshop Practice ComponentsAliah IzzahNo ratings yet

- Workpiece and tool measurement with TS and TT touch probesDocument4 pagesWorkpiece and tool measurement with TS and TT touch probesemo_waggyNo ratings yet

- Cutting Speed Feed For Milling MachineDocument21 pagesCutting Speed Feed For Milling MachineKeerthi Kumar100% (1)

- PVC PLasticisersDocument2 pagesPVC PLasticisersKrishna PrasadNo ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- Explain The Types and Properties of Smart Material ?Document7 pagesExplain The Types and Properties of Smart Material ?rautsushant21No ratings yet

- Explain The Types and Properties of Smart Material ?Document7 pagesExplain The Types and Properties of Smart Material ?rautsushant21No ratings yet

- C 2920 35 PDFDocument140 pagesC 2920 35 PDFHarish ChandrashekarNo ratings yet

- Introduction To Oracle GroovyDocument53 pagesIntroduction To Oracle GroovyDeepak BhagatNo ratings yet

- Java10 PDFDocument137 pagesJava10 PDFswarup sarkarNo ratings yet

- Drill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsDocument7 pagesDrill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsSasan AbbasiNo ratings yet

- SDH TechnologyDocument26 pagesSDH TechnologyJayesh SinghalNo ratings yet

- Carbide GradesDocument51 pagesCarbide GradesRicardo BravoNo ratings yet

- Bilstein SZ SL Sls 2010Document16 pagesBilstein SZ SL Sls 2010Wimin HungNo ratings yet

- WPS Office 2016Document22 pagesWPS Office 2016Muhammad Aliff SyukriNo ratings yet

- LTE and SchedulingDocument25 pagesLTE and SchedulingKrunoslav IvesicNo ratings yet

- End Mill Training Website PDFDocument64 pagesEnd Mill Training Website PDFDejan Jovanovic100% (1)

- Speed and Feed For Lathe MachiningDocument6 pagesSpeed and Feed For Lathe MachiningThinesh ChanderNo ratings yet

- Belt PulleysDocument124 pagesBelt Pulleyse.vicente.caballero100% (1)

- Cutting Speeds and Feeds GuideDocument4 pagesCutting Speeds and Feeds GuideAnonymous dh6DITNo ratings yet

- Assingment 2: Manufacturing TechnologyDocument29 pagesAssingment 2: Manufacturing TechnologySarweshNarayanParbatNo ratings yet

- Feed Rate CalculationsDocument4 pagesFeed Rate CalculationsJesus Said Mercado VegaNo ratings yet

- 1 IntroductionDocument33 pages1 IntroductionNebojsa NunicNo ratings yet

- Thread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM)Document3 pagesThread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM)Bv RaoNo ratings yet

- BSP Pipe ThreadDocument1 pageBSP Pipe ThreadgvmindiaNo ratings yet

- EML2322L-Drilling and Milling Speeds and FeedsDocument9 pagesEML2322L-Drilling and Milling Speeds and Feedsjromero_rpgNo ratings yet

- Form Tap DrillDocument2 pagesForm Tap DrillMed AliNo ratings yet

- Mastercam Handbook Volume 1, Chapter 9, Rotary ToolpathsDocument22 pagesMastercam Handbook Volume 1, Chapter 9, Rotary ToolpathsanvilfabNo ratings yet

- Fanuc Touch Probe Cycles GuideDocument6 pagesFanuc Touch Probe Cycles Guidesonnv_hcmuteNo ratings yet

- My CNC TurningDocument7 pagesMy CNC Turningde_stanszaNo ratings yet

- Sodick Technology SelectorDocument14 pagesSodick Technology SelectorTrần Văn TrườngNo ratings yet

- TNC 426 TNC 430: User's Manual Conversational ProgrammingDocument374 pagesTNC 426 TNC 430: User's Manual Conversational ProgrammingСлоба ЈовановићNo ratings yet

- Measuring Cutting Forces PDFDocument14 pagesMeasuring Cutting Forces PDFprof_panneerNo ratings yet

- Mastercam Handbook Volume 1, IntroductionDocument8 pagesMastercam Handbook Volume 1, IntroductionanvilfabNo ratings yet

- CNC Programming Functions GuideDocument68 pagesCNC Programming Functions GuideJon Morales100% (1)

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Document24 pagesSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNo ratings yet

- Thread Milling TutorialDocument9 pagesThread Milling TutorialThirugnanam DhandayuthapaniNo ratings yet

- Mill Lesson 2Document27 pagesMill Lesson 2Putra PuguhNo ratings yet

- MTM Lab PresentationDocument26 pagesMTM Lab PresentationMuhammad WaseemNo ratings yet

- American Filler MetalsDocument13 pagesAmerican Filler MetalsĐình NamNo ratings yet

- Body Bulding TipsDocument9 pagesBody Bulding TipsMD Jakir HossenNo ratings yet

- Setup SheetsDocument4 pagesSetup SheetsThirugnanam DhandayuthapaniNo ratings yet

- CNC MachinesDocument52 pagesCNC Machinespranav sharmaNo ratings yet

- Cam Lab ManualDocument14 pagesCam Lab Manualelangandhi0% (1)

- CNC Mill TutorialDocument17 pagesCNC Mill TutorialvanchiencncNo ratings yet

- V9.1 Lathe Tutorial Change Pages (Inch)Document39 pagesV9.1 Lathe Tutorial Change Pages (Inch)Andrew TNo ratings yet

- 4th Axis Pocket Mastercam TutorialDocument8 pages4th Axis Pocket Mastercam TutorialAlaek Nu'manNo ratings yet

- Comprehensive Tool Descriptions-1Document54 pagesComprehensive Tool Descriptions-1pocerilloNo ratings yet

- Four Axis Lesson 1 SampleDocument18 pagesFour Axis Lesson 1 Sampletuanvn76No ratings yet

- DIN 69871 enDocument69 pagesDIN 69871 enalphatoolsNo ratings yet

- HaasLiveToolOpProgram - W - DS Manual PDFDocument70 pagesHaasLiveToolOpProgram - W - DS Manual PDFGuillermo RamirezNo ratings yet

- Four Axis Lesson 1 SampleDocument27 pagesFour Axis Lesson 1 SampleLuis Enrique FloresNo ratings yet

- Inventorcam 2014 Application Tutorial: Multiblade Machining: ©1995-2013 Solidcam All Rights ReservedDocument45 pagesInventorcam 2014 Application Tutorial: Multiblade Machining: ©1995-2013 Solidcam All Rights ReservedKhai Huynh100% (1)

- Machining Center: Monday, April 20, 2020 Mechanical Engineering DepartmentDocument165 pagesMachining Center: Monday, April 20, 2020 Mechanical Engineering DepartmentAmit T.100% (1)

- SAMPLE MastercamX9 Beginner TrainingTutorialDocument56 pagesSAMPLE MastercamX9 Beginner TrainingTutorialCristian FuentesNo ratings yet

- Calculation Manufacturing ProcessDocument18 pagesCalculation Manufacturing ProcessEncik MaaNo ratings yet

- Vic-3D Online Manual: Navigating The Help SystemDocument94 pagesVic-3D Online Manual: Navigating The Help SystemMew JonathanNo ratings yet

- CNC and MastercamDocument18 pagesCNC and MastercambellaNo ratings yet

- MASTERCAM - PocketDocument23 pagesMASTERCAM - PocketcostycgNo ratings yet

- Seco ToolsDocument24 pagesSeco ToolscortelinirosaNo ratings yet

- NC, CNC & Robotics: An IntroductionDocument143 pagesNC, CNC & Robotics: An IntroductionshafiqNo ratings yet

- Krar Unit 41Document14 pagesKrar Unit 41Amir AmiriNo ratings yet

- Cutting Speed Feed and DOC2Document21 pagesCutting Speed Feed and DOC2Riko PrakosoNo ratings yet

- Chapter 5 - CNC ToolingDocument50 pagesChapter 5 - CNC ToolingDani AbHalimNo ratings yet

- Cutting Speed, Feed, and Depth of Cut for Lathe OperationsDocument22 pagesCutting Speed, Feed, and Depth of Cut for Lathe OperationsThanin AmnuayviboonphonNo ratings yet

- Manufacturing Processes (Machining Processes & Machine Tools) (Beng) (Handout)Document82 pagesManufacturing Processes (Machining Processes & Machine Tools) (Beng) (Handout)bananaNo ratings yet

- Cutting Speed Feed andDocument22 pagesCutting Speed Feed andHeinz D'Curva SudNo ratings yet

- Thermally Conductive MaterialDocument15 pagesThermally Conductive Materialrautsushant21No ratings yet

- Die CastDocument17 pagesDie Castrautsushant21No ratings yet

- Material Selection CriteriaDocument2 pagesMaterial Selection Criteriarautsushant21No ratings yet

- Me 1998 Gate PaperDocument14 pagesMe 1998 Gate Paperrautsushant21No ratings yet

- Die CastDocument17 pagesDie Castrautsushant21No ratings yet

- Die CastDocument17 pagesDie Castrautsushant21No ratings yet

- FMEADocument13 pagesFMEArautsushant21No ratings yet

- Me 1994 Gate PaperDocument10 pagesMe 1994 Gate Paperrautsushant21No ratings yet

- Me 1997 Gate PaperDocument13 pagesMe 1997 Gate PaperSahil SharmaNo ratings yet

- Me 1992Document7 pagesMe 1992Rahul KusumaNo ratings yet

- Me 1993 Gate PaperDocument4 pagesMe 1993 Gate Paperrautsushant21No ratings yet

- Ain 2016 Pilot Report m600Document4 pagesAin 2016 Pilot Report m600Antonio Cesar de Sa LeitaoNo ratings yet

- PEE3-M Lec 1Document19 pagesPEE3-M Lec 1Ena Leanica DelgadoNo ratings yet

- 2017 Yr 9 Linear Relations Test A SolutionsDocument13 pages2017 Yr 9 Linear Relations Test A SolutionsSam JeffreyNo ratings yet

- Canalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Document324 pagesCanalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Rubén González CabreraNo ratings yet

- ChamSys Touchscreen SupportDocument2 pagesChamSys Touchscreen SupportKayla PadillaNo ratings yet

- Solution of Homework 4Document4 pagesSolution of Homework 4Kamalakar Reddy100% (2)

- Product Presentation Nova Blood Gas AnalyzerDocument38 pagesProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Manual 1Document37 pagesManual 1Şahin GüngörNo ratings yet

- 08 Candelaria Punta Del Cobre IOCG Deposits PDFDocument27 pages08 Candelaria Punta Del Cobre IOCG Deposits PDFDiego Morales DíazNo ratings yet

- Impedance Measurement Handbook: 1st EditionDocument36 pagesImpedance Measurement Handbook: 1st EditionAlex IslasNo ratings yet

- Design Plan: A Performance Task in GeometryDocument12 pagesDesign Plan: A Performance Task in GeometryRobert Ryan SantiagoNo ratings yet

- Stereochemistry Practce PDFDocument6 pagesStereochemistry Practce PDFFerminNo ratings yet

- Cross Belt Magnetic Separator (CBMS)Document2 pagesCross Belt Magnetic Separator (CBMS)mkbhat17kNo ratings yet

- WebControls - TabStripDocument38 pagesWebControls - TabStripProkopis PrNo ratings yet

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenqueNo ratings yet

- PresiometroDocument25 pagesPresiometrojoseprepaNo ratings yet

- Numeri OrdinaliDocument2 pagesNumeri OrdinaliClaudioNo ratings yet

- Module 4 - What Is The Required Rate of ReturnDocument2 pagesModule 4 - What Is The Required Rate of ReturnEthics BAENo ratings yet

- Classification of Differential Equations For Finding Their SolutionsDocument2 pagesClassification of Differential Equations For Finding Their SolutionsakhileshNo ratings yet