Professional Documents

Culture Documents

Productivity

Uploaded by

Peter CalvoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Productivity

Uploaded by

Peter CalvoCopyright:

Available Formats

1

2

Single-factor measures

Output / (Single Input)

All-factors measure

Output / (Total Inputs)

Productivity =

Outputs

Inputs

Productivity

3

Single-factor Output Output Output Output

measures Labor Machine Capital Energy

All-factors Output

measure All inputs

Measures of Productivity

4

Single-factor Output Output Output Output

measures Labor Machine Capital Energy

If we produce only one product, the numerator can be either

the total units of the product or the total $ value of the

product. If we produce several products, the numerator is

the total $ value of all products.

The denominator can be the units of input or the total $

value of input.

Single Factor

5

10,000 Units Produced

Sold for $10/unit

500 labor hours

Labor rate: $9/hr

What is the

labor productivity?

Example: Single Factor Productivity

6

10,000 units / 500hrs = 20 units/hr

(10,000 units * $10/unit) / 500hrs = $200/hr

10,000 units / (500hrs * $9/hr) = 2.2 unit/$

(10,000 units * $10/unit) / (500hrs * $9/hr) = 22.22

The last one is unit-less

Example: Labor Productivity

7

Labor Productivity

Quantity (or value) of output / labor hrs

Quantity (or value) of output / shift

Machine Productivity

Quantity (or value) of output / machine hrs

Energy Productivity

Quantity (or value of output) / kwh

Capital Productivity

Quantity (or value) of output / value of input

Some Single Factor Measurements

8

All-factors Goods or Services produced

measure All inputs used to produce them

If we produce only one product, the numerator can be either

the total units of product or total $ value of the product.

If we produce several products, the numerator is the total

$ value of all products.

Usually, the numerator is the total $ value of all outputs.

The denominator is total $ value of all inputs.

All Factors

9

10,000 Units Produced

Sold for $10/unit

500 labor hours

Labor rate: $9/hr

Cost of raw material: $30,000

Overhead: $15,500

Example

10

Output

Labor + Materials + Overhead

(10,000 units) * ($10)

(500)*($9) + ($30,000) + ($15,500)

AFP = 2.0

Example : All-Factor Productivity

AFP =

AFP =

11

Training Methods

Technology Management

What are the factors that affect productivity?

12

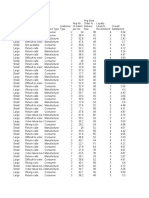

1. A company that makes shopping carts for supermarkets recently purchased

new equipment, which reduced the labor content needed to produce the

carts. Information concerning the old system (before adding the new

equipment) and the new system (after adding the new machines) includes:

Old System New System

Output/hr 80 84

Workers 5 4

Wage $/hr 10 10

Machine $/hr 40 50

a) Compute labor productivity for both the Old System and the New System.

b) Compute AFP productivity for both the Old System and the New System.

c) Suppose production with old equipment was 30 units of cart A at a price of

$100 per cart, and 50 units of cart B at a price of $120. Also suppose that

production with new equipment is 50 units of cart A, at a price of $100 per

cart, and 30 units of cart B at a price of $120. Compare all-factor productivity

for the old and the new systems.

Assignment 1.1.. Due at the beginning of the next class

13

Assignment 1.2.. Due at the beginning of the next class

2. A company has introduced a process improvement that reduces the

processing time for each unit and increases output by 25% with less

material but one additional worker.

Under the old process, five workers could produce 60 units per hour.

Labor costs are $12/hour, and material input was $16/unit.

For the new process, material input is now $10/unit and overhead is

charged at 1.6 times direct labor cost. Finished units sell for $31 each.

a) Compute single factor productivity of labor in the old system.

(Compute it in four possible ways.)

b) Compute all factor productivity for both old and new systems.

Factor Old System New System

Output 60 60(1.25) = 75

# of workers 5 6

Worker cost $12/hr $12/hr

Material $16/unit $10/unit

Overhead 1.6(labor cost) 1.6(labor cost)

Price 31 31

14

Assignment 1.3 For your own practice

3. A milk factory seeks advice from an external consulting company concerning its

business and production processes. The final consulting report describes

several steps to increase productivity including implementation of cutting-edge

processing techniques through more powerful filtering systems.

a) Calculate the labor productivity for the existing as well as the proposed system.

b) Find the All-Factor Productivity for both systems.

c) Assume that current processing includes 700 gallons of Grade-A milk sold at

$2.40/gallon and 300 gallons of Grade-B milk at $1.90/gallon. Furthermore,

assume that under the proposed system, processing will include 600 gallons of

Grade-A milk at $2.40/gallon and 400 gallons of Grade-B milk at $1.90/gallon.

Compare all-factor productivity for both the existing and the new system.

Existing System Proposed System

Workers 12 9

Milk Output/hour 1,000 gallons 1,400 gallons

Wage Rate/hour $12 $12

Filtration Cost/hour $120 $170

You might also like

- Six Sigma Yellow Belt: Introduction to Lean six Sigma Methodology for BeginnersFrom EverandSix Sigma Yellow Belt: Introduction to Lean six Sigma Methodology for BeginnersNo ratings yet

- Heijunka 29.3.19Document27 pagesHeijunka 29.3.19rohitNo ratings yet

- Lean ManufacturingDocument20 pagesLean ManufacturingPranav SharmaNo ratings yet

- JIT Operations Management Week 14Document37 pagesJIT Operations Management Week 14Muhammad Arsalan ChouhanNo ratings yet

- Manufacturing CellDocument19 pagesManufacturing CellRavi Nawal100% (1)

- Seven Basic Quality Tools: List / Use / InteractionDocument56 pagesSeven Basic Quality Tools: List / Use / InteractionmangofaNo ratings yet

- Method Study TechniquesDocument28 pagesMethod Study TechniquesPatel KunalNo ratings yet

- Shanin Techniques Jo MoorenDocument3 pagesShanin Techniques Jo MoorenAnonymous X0iytQQYJ6No ratings yet

- Time and Motion StudyDocument23 pagesTime and Motion StudyLlehk FranciscoNo ratings yet

- TQMDocument46 pagesTQMjillmehta14No ratings yet

- Six Sigma Green Belt Project Purchasing ProcessDocument18 pagesSix Sigma Green Belt Project Purchasing ProcessKrish0% (1)

- Motion and Time Study (Practical)Document18 pagesMotion and Time Study (Practical)Francois de VilliersNo ratings yet

- Assembly Line BalancingDocument5 pagesAssembly Line Balancingabhijitsamanta1100% (1)

- JIT - JidokaDocument23 pagesJIT - JidokaViraj DhuriNo ratings yet

- The DefinitionDocument9 pagesThe DefinitionRitesh ChoudharyNo ratings yet

- 10 Days Nos TrainingDocument511 pages10 Days Nos Trainingdayat hidayatNo ratings yet

- 6.4 Process CapabilityDocument13 pages6.4 Process CapabilitychuszNo ratings yet

- 1.5 LSS Quality Files Bus. Risk ManagementDocument81 pages1.5 LSS Quality Files Bus. Risk ManagementMurrell J RizonNo ratings yet

- Unblocking BottlenecksDocument3 pagesUnblocking BottlenecksMaggie GonzalesNo ratings yet

- Principles of Lean ManufacturingDocument23 pagesPrinciples of Lean Manufacturingkiran2381100% (1)

- Multi Vari ChartsDocument9 pagesMulti Vari ChartsDearRed FrankNo ratings yet

- Lean Manufacturing REPORTDocument15 pagesLean Manufacturing REPORTSandeep GrNo ratings yet

- House of Quality Examples Guide Featuring Rock-Climbing Harness AnalysisDocument9 pagesHouse of Quality Examples Guide Featuring Rock-Climbing Harness AnalysisKresna NoviardityaNo ratings yet

- Line Balancing ExplainedDocument23 pagesLine Balancing ExplainedArun MishraNo ratings yet

- Cellular ManufacturingDocument25 pagesCellular ManufacturingApoorv Mathur100% (1)

- Value Stream Mapping: Dr. Richard E. WhiteDocument19 pagesValue Stream Mapping: Dr. Richard E. WhiteSamir ChaudhariNo ratings yet

- WCM Principle 4 HeijunkaDocument33 pagesWCM Principle 4 HeijunkaSaurabh KothawadeNo ratings yet

- Meet Customer Requirements with Process CapabilityDocument30 pagesMeet Customer Requirements with Process CapabilityAniket Jain100% (2)

- Elementary Quality Assurance ToolsDocument19 pagesElementary Quality Assurance ToolsignaunaqNo ratings yet

- Operational ExcellenceDocument61 pagesOperational ExcellenceNurul HidayahNo ratings yet

- Theory of Constraints: Drum Buffer RopeDocument29 pagesTheory of Constraints: Drum Buffer RopeMohit SrivastavaNo ratings yet

- 8DDocument117 pages8DLokesh NarasimhaiahNo ratings yet

- An Application of SMED Methodology PDFDocument4 pagesAn Application of SMED Methodology PDFIng Raul OrozcoNo ratings yet

- Lean Manufacturing & TPMDocument2 pagesLean Manufacturing & TPMEdward GermánNo ratings yet

- Submitted By,: Jarzid Alam Alomgir Badsha Saif MahabubDocument26 pagesSubmitted By,: Jarzid Alam Alomgir Badsha Saif MahabubSaif KhanNo ratings yet

- Affinity DiagramDocument1 pageAffinity DiagramFahad MaqsoodNo ratings yet

- Lean ManufacturingDocument17 pagesLean ManufacturingAmbarish100% (6)

- Functional Point Estimation MethodsDocument14 pagesFunctional Point Estimation MethodsShalaka KulkarniNo ratings yet

- Lean Six Sigma Project CharterDocument1 pageLean Six Sigma Project CharterPedro KNo ratings yet

- Boost productivity with Total Factor Productivity analysisDocument72 pagesBoost productivity with Total Factor Productivity analysisSameer Sawant100% (1)

- STATISTICAL PROCESS CONTROL OVERVIEWDocument116 pagesSTATISTICAL PROCESS CONTROL OVERVIEWRohit JanardananNo ratings yet

- Teppi Tevet College Apply 3S: KaizenDocument60 pagesTeppi Tevet College Apply 3S: KaizenPunitha Paul0% (1)

- Lean-7waste, Takt Time, Crew SizeDocument80 pagesLean-7waste, Takt Time, Crew Sizeapi-3770121100% (2)

- Multivari CHARTSDocument16 pagesMultivari CHARTSanujkumartyagi9275No ratings yet

- VARSIGMA - GB - Preparatory Module V1.1 PDFDocument104 pagesVARSIGMA - GB - Preparatory Module V1.1 PDFCharanjeetSinghKhanujaNo ratings yet

- Rolled Throughput Yield (Training)Document7 pagesRolled Throughput Yield (Training)Madhavan RamNo ratings yet

- 1034 Value Stream Mapping TemplateDocument3 pages1034 Value Stream Mapping TemplateKlaudiaNo ratings yet

- BMW IMAC Form Completeness Six Sigma Case StudyDocument2 pagesBMW IMAC Form Completeness Six Sigma Case StudySteven BonacorsiNo ratings yet

- Core Tools (Apqp, Dfmea, Pfmea, Control Plans, Ppap, SPC, Msa) 5 Days TrainingDocument2 pagesCore Tools (Apqp, Dfmea, Pfmea, Control Plans, Ppap, SPC, Msa) 5 Days TrainingAnkur DhirNo ratings yet

- Lean - Standard WorkDocument9 pagesLean - Standard WorkBalaji SNo ratings yet

- Process and Measurement System Capability AnalysisDocument18 pagesProcess and Measurement System Capability AnalysisUtkarsh MittalNo ratings yet

- Kano Model PDFDocument5 pagesKano Model PDFdanielmugaboNo ratings yet

- Lean ManufacturingDocument47 pagesLean ManufacturingSaumya SaumyaNo ratings yet

- DfmeaDocument13 pagesDfmeaAshisNo ratings yet

- Machine Capability For Process AuditsDocument4 pagesMachine Capability For Process AuditsBrian Pringle0% (2)

- Lean Tool PDFDocument2 pagesLean Tool PDFTuong Tan100% (1)

- Project Quality Management A Complete Guide - 2019 EditionFrom EverandProject Quality Management A Complete Guide - 2019 EditionNo ratings yet

- Company Name or Logo List of Employees: BranchDocument1 pageCompany Name or Logo List of Employees: BranchPeter CalvoNo ratings yet

- LEARN TO ADAPT TO CHANGE THROUGH EFFECTIVE CHANGE MANAGEMENTDocument24 pagesLEARN TO ADAPT TO CHANGE THROUGH EFFECTIVE CHANGE MANAGEMENTPeter CalvoNo ratings yet

- Change Is LifeDocument14 pagesChange Is LifePeter CalvoNo ratings yet

- Plastic Caps Moulding Machine Production & MaintenanceDocument204 pagesPlastic Caps Moulding Machine Production & MaintenancePeter Calvo90% (10)

- Managing Change EffectivelyDocument18 pagesManaging Change EffectivelyPeter CalvoNo ratings yet

- 422rfhcpu eDocument150 pages422rfhcpu eSkinny1001No ratings yet

- Training Need AnalysisDocument2 pagesTraining Need AnalysisPeter CalvoNo ratings yet

- Skills Development Training Profile 2008-2009Document2 pagesSkills Development Training Profile 2008-2009Peter CalvoNo ratings yet

- 424ish eDocument316 pages424ish ePeter CalvoNo ratings yet

- Carlo Gavazzi Level RelayDocument5 pagesCarlo Gavazzi Level RelayPeter CalvoNo ratings yet

- Modem ManualDocument82 pagesModem Manualcwgirlatheart100% (1)

- Acer Aspire 5738 5738z User ManualDocument13 pagesAcer Aspire 5738 5738z User ManualSeona LeeNo ratings yet

- 3200A Automatic Transfer SwitchDocument8 pages3200A Automatic Transfer SwitchKCFUNGNo ratings yet

- Sivacon SwitchboardsDocument28 pagesSivacon SwitchboardsAndrei DanielNo ratings yet

- Enclosure Nema and IP Rating BasicsDocument2 pagesEnclosure Nema and IP Rating BasicsPeter CalvoNo ratings yet

- 3200A Automatic Transfer SwitchDocument8 pages3200A Automatic Transfer SwitchKCFUNGNo ratings yet

- Atn Cat Eng 130808Document7 pagesAtn Cat Eng 130808Peter CalvoNo ratings yet

- EggRecipes p10Document3 pagesEggRecipes p10Peter CalvoNo ratings yet

- Carrier Control 02 2008Document40 pagesCarrier Control 02 2008Javier SordoNo ratings yet

- Per UnitDocument18 pagesPer UnitPeter CalvoNo ratings yet

- How To Build An Electrical Maintenance ProgramDocument5 pagesHow To Build An Electrical Maintenance ProgramPeter CalvoNo ratings yet

- DMAIC Roadmap for Process ImprovementDocument13 pagesDMAIC Roadmap for Process ImprovementPeter CalvoNo ratings yet

- EggRecipes p32Document3 pagesEggRecipes p32Peter CalvoNo ratings yet

- Product Data Sheet 6ES7131-4BF00-0AA0Document3 pagesProduct Data Sheet 6ES7131-4BF00-0AA0Peter CalvoNo ratings yet

- EggRecipes p27Document3 pagesEggRecipes p27Peter CalvoNo ratings yet

- EggRecipes p35Document3 pagesEggRecipes p35Peter CalvoNo ratings yet

- EggRecipes p24Document4 pagesEggRecipes p24Peter CalvoNo ratings yet

- Assess your HR function with this checklistDocument5 pagesAssess your HR function with this checklistRahul GoleNo ratings yet

- EggRecipes p21Document2 pagesEggRecipes p21Peter CalvoNo ratings yet

- Var, CaR, CAR, Basel 1 and 2Document7 pagesVar, CaR, CAR, Basel 1 and 2ChartSniperNo ratings yet

- Masters of Death: The Assassin ClassDocument5 pagesMasters of Death: The Assassin Classjbt_1234No ratings yet

- Creating Early Learning Environments PDFDocument25 pagesCreating Early Learning Environments PDFkrisnahNo ratings yet

- Kerala Dinesh Beedi - WikipediaDocument12 pagesKerala Dinesh Beedi - Wikipediaaymanamna2016No ratings yet

- Cub Cadet 1650 PDFDocument46 pagesCub Cadet 1650 PDFkbrckac33% (3)

- Introduction To Mass Communication Solved MCQs (Set-3)Document5 pagesIntroduction To Mass Communication Solved MCQs (Set-3)Abdul karim MagsiNo ratings yet

- 2006 - Bykovskii - JPP22 (6) Continuous Spin DetonationsDocument13 pages2006 - Bykovskii - JPP22 (6) Continuous Spin DetonationsLiwei zhangNo ratings yet

- Geller (LonginusRhetoric'sCure)Document27 pagesGeller (LonginusRhetoric'sCure)Miguel AntónioNo ratings yet

- Write The Missing Words of The Verb To Be (Affirmative Form)Document1 pageWrite The Missing Words of The Verb To Be (Affirmative Form)Daa NnaNo ratings yet

- KNJN Fpga Pluto-P BoardDocument15 pagesKNJN Fpga Pluto-P Boardgandalf1024No ratings yet

- 5.2.1 1539323575 2163Document30 pages5.2.1 1539323575 2163Brinda TNo ratings yet

- Effects of Violence On Transgender PeopleDocument8 pagesEffects of Violence On Transgender PeopleAdel Farouk Vargas Espinosa-EfferettNo ratings yet

- Relation of Sociology with other social sciencesDocument4 pagesRelation of Sociology with other social sciencesBheeya BhatiNo ratings yet

- Otis, Elisha Graves REPORTDocument7 pagesOtis, Elisha Graves REPORTrmcclary76No ratings yet

- Reviewer in Intermediate Accounting IDocument9 pagesReviewer in Intermediate Accounting ICzarhiena SantiagoNo ratings yet

- 15-8377 - 3521 Calandria Communications L. Rivera PDFDocument20 pages15-8377 - 3521 Calandria Communications L. Rivera PDFRecordTrac - City of OaklandNo ratings yet

- Doña PerfectaDocument317 pagesDoña PerfectadracbullNo ratings yet

- The Mckenzie MethodDocument24 pagesThe Mckenzie MethodMohamed ElMeligieNo ratings yet

- 4 5895601813654079927 PDFDocument249 pages4 5895601813654079927 PDFqabsNo ratings yet

- Theory of Karma ExplainedDocument42 pagesTheory of Karma ExplainedAKASH100% (1)

- Schumann Op15 No5 PsuDocument1 pageSchumann Op15 No5 PsuCedric TutosNo ratings yet

- The Big Banana by Roberto QuesadaDocument257 pagesThe Big Banana by Roberto QuesadaArte Público Press100% (2)

- Bluetooth® (SAP) Telephone Module, Version 4Document2 pagesBluetooth® (SAP) Telephone Module, Version 4Željko BokanovićNo ratings yet

- Importance of Time Management To Senior High School Honor StudentsDocument7 pagesImportance of Time Management To Senior High School Honor StudentsBien LausaNo ratings yet

- Apexocardiograma Precizari PracticeDocument12 pagesApexocardiograma Precizari PracticeDaniel VelciuNo ratings yet

- Lauritzen 1964Document10 pagesLauritzen 1964Priyanka GandhiNo ratings yet

- Subsurface Sewage DisposalDocument174 pagesSubsurface Sewage DisposalSanthi KrishnaNo ratings yet

- Role of Islamic Crypto Currency in Supporting Malaysia's Economic GrowthDocument6 pagesRole of Islamic Crypto Currency in Supporting Malaysia's Economic GrowthMarco MallamaciNo ratings yet

- Chinnamasta Sadhana PDFDocument1 pageChinnamasta Sadhana PDFSayan Majumdar100% (2)

- Operations Management Dr. Loay Salhieh Case Study #1: Students: Hadil Mosa Marah Akroush Mohammad Rajab Ousama SammawiDocument6 pagesOperations Management Dr. Loay Salhieh Case Study #1: Students: Hadil Mosa Marah Akroush Mohammad Rajab Ousama SammawiHadeel Almousa100% (1)