Professional Documents

Culture Documents

CE336 09 Corrosion

Uploaded by

Muhammad Adli Bin Ja'affarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE336 09 Corrosion

Uploaded by

Muhammad Adli Bin Ja'affarCopyright:

Available Formats

Corrosion & Associated Degradation

Objectives

Corrosion process

Environmental factors

Common forms of corrosion

Methods of corrosion control

and prevention

Metal Corrosion

the destruction of a material by

chemical or electrochemical reaction to

its environment

typically a transfer of electrons from

one metal to another through an

Oxidation-Reduction Reaction.

Oxidation - Reduction

Reduction

Anodic metal gives up electrons (oxidation)

Cathodic metal accepts electrons (reduction)

Or gases accept electrons (reduction)

Fe Fe e

2

2

Al Al e

3

3

Cu e Cu

2

2

2 2

2

H e H gas

( )

Corrosion Mechanism

Cathodic cell

discussion of emf

galvanic series

intergranular corrosion

oxidation-reduction of iron

salt effects

Slides on Impact of Corrosion

Aluminum corrosion

Pitting

Crevice corrosion

Contaminants

Environments

Basics of Corrosion

EMF series is a numeric rating of

potential under ideal conditions

Galvanic Series is a practical listing

Galvanic Protection

Steel Corrosion

2 2 2

2 2 2

Fe O H O Fe OH ( )

2

1

2

2

2 2 2 3

Fe OH O H O Fe OH ( ) ( )

Initial Oxidation Reaction

Secondary Oxidation Reaction

Rust

Corrosion potential calculation

Reduction Reaction must have higher

potential than the oxidation reaction or

they will not form a cathodic cell

Fe e Fe

2

2

-0.440 V

Zn e Zn

2

2

-0.763 V

V V . . . 440 763 0323

Relative measure of

corrosion

Acceleration of Corrosion

Physical Characteristics

exposed area (less, increases corrosion rate)

time of exposure (more time, more corrosion)

Environmental Characteristics

acidic environment

sulfur gas environment

temperature (high temps, more corrosion)

moisture (oxygenated moisture)

Passivation

A protective film in oxidizing atmospheres

chromium,nickel, titanium, aluminum

Metal oxide layer adheres to parent metal

barrier against further damage

self-healing if scratched

Sensitive to environmental conditions

passivated metal may have high corrosion rates

Forms of Corrosion

Uniform corrosion of a single metal

usually an electrochemical reaction at

granular level

relatively slow and predictable

rusting of exposed steel, tarnished silver

easily corrected with coatings and regular

maintenance

Forms of Corrosion

Galvanic Corrosion

2 dissimilar metals, electrolyte, electrical

connection and oxygen

Pitting Corrosion

Localized corrosion forming holes or

indentations

Difficult to initially detect

Forms of Corrosion

Crevice Corrosion

narrow crevice filled with ionized solution

Oxygen-rich on the outside, oxygen-poor

on the inside

metals oxidize with salt anions FeCl

2

and

pH rises in cathodic zone

H

+

may destroy passivity

Forms of Corrosion

Intergranular Corrosion

corrosion along grain boundaries at

microscopic level

stainless steels and heat treated high-

strength steels

carbides precipitate along grain boundaries

leaving these areas with no alloyed

Chromium

Welds can have this same depletion effect

Forms of Corrosion

Cavitation and Erosion in Pipe

particulate matter

turbulent flow

abrades away the corrosion product

abrasion of zinc coatings

Forms of Corrosion

Stress Corrosion Cracking

tensile stress and corrosive environments

cracks are initiated at corrosion areas

tensile stresses propagate the crack

corrosion further deteriorate crack

etc.....

Reinforcement Corrosion

Corrosion Products

Fe + 2OH =

Fe(OH)

2

Oxidation of Fe(OH)

2

Fe(OH)

3

(rust)

Passivity barrier

breaks down

Presence of Oxygen

Moisture

Corrosion of Metals in Concrete

Reinforcing Steel & Prestressing Steel

Concrete is Normally Highly Alkaline

Protects Steel from Rusting if Properly Embedded

If Corrosion Occurs, the Reaction Products are

Greater in Volume Than the Original Steel

Corrosion Initiation and Rate Depends On

Amount of Concrete Cover, Quality of Concrete

Details of Construction, & Exposure to Chlorides

Avoiding Corrosive Situations

Choose couple metals close on the galvanic

series

Use large anode, and small cathode areas

Electrically insulate dissimilar metals

Connect a more anodic metal to the system

Avoid turbulent flow and impingements in

pipe systems

Examples of Corrosion in CE

Steel strapping or

iron nails with

copper pipe is ok,

but they may rust

with time.

Never use Copper

strapping or

attachments with

steel pipe, steel pipe

will corrode

condensation on the bottom

of cold water pipe

Corrosion Prevention

Coatings

Barrier films

Inhibitive Pigments

Sacrificial

treatments

Paint

Active Cathodic

Protection

You might also like

- Maritime Economics & TransportationDocument4 pagesMaritime Economics & TransportationMuhammad Adli Bin Ja'affarNo ratings yet

- Harmonized System and Procedure of Importation & ExportationDocument22 pagesHarmonized System and Procedure of Importation & ExportationMuhammad Adli Bin Ja'affarNo ratings yet

- Assignment: Cabotage PolicyDocument15 pagesAssignment: Cabotage PolicyMuhammad Adli Bin Ja'affar100% (1)

- WATERTUBE boiler components guideDocument2 pagesWATERTUBE boiler components guideMuhammad Adli Bin Ja'affarNo ratings yet

- Propeller 1 DesignDocument13 pagesPropeller 1 DesignMuhammad Adli Bin Ja'affarNo ratings yet

- Maritime Law in MalaysiaDocument26 pagesMaritime Law in MalaysiaKhairil Anuar Yusof100% (1)

- LGB 40503 Assignment 1 Presentation MarkingDocument3 pagesLGB 40503 Assignment 1 Presentation MarkingMuhammad Adli Bin Ja'affarNo ratings yet

- AGA Aluminium Welding Facts About UKDocument16 pagesAGA Aluminium Welding Facts About UKMuhammad Adli Bin Ja'affarNo ratings yet

- Cerritos College Welding Safety PoliciesDocument2 pagesCerritos College Welding Safety PoliciesMuhammad Adli Bin Ja'affarNo ratings yet

- Punting Its History and TechniquesDocument27 pagesPunting Its History and TechniquesMuhammad Adli Bin Ja'affarNo ratings yet

- Propeller 1 DesignDocument13 pagesPropeller 1 DesignMuhammad Adli Bin Ja'affarNo ratings yet

- Ch10 2Document13 pagesCh10 2Muhammad Adli Bin Ja'affarNo ratings yet

- OSV Condor PDFDocument3 pagesOSV Condor PDFMuhammad Adli Bin Ja'affar0% (1)

- Introduction For Fundamentals EnglishDocument8 pagesIntroduction For Fundamentals EnglishMuhammad Adli Bin Ja'affarNo ratings yet

- Small Angle Stability-Longi Compatibility ModeDocument18 pagesSmall Angle Stability-Longi Compatibility ModeMuhammad Adli Bin Ja'affarNo ratings yet

- VG-110/D-700 VG-110/D-700: Instruction ManualDocument74 pagesVG-110/D-700 VG-110/D-700: Instruction ManualMuhammad Adli Bin Ja'affarNo ratings yet

- LNB 20303-Naval Architecture 1 - Lesson PlanDocument2 pagesLNB 20303-Naval Architecture 1 - Lesson PlanMuhammad Adli Bin Ja'affarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Surface treatments for automotive applicationsDocument7 pagesSurface treatments for automotive applicationsSasiKumar PetchiappanNo ratings yet

- Penna Cement Corporate ProfileDocument4 pagesPenna Cement Corporate Profilesagarcholke100% (1)

- Rheo FibreDocument2 pagesRheo FibreBinoy Sankar SarkerNo ratings yet

- Wood Connectors - Houtverbindingen - 2013 - LRDocument168 pagesWood Connectors - Houtverbindingen - 2013 - LRjanm2008No ratings yet

- Grain Refinement MechanismsDocument8 pagesGrain Refinement MechanismsFolo Daniel SianiparNo ratings yet

- Journal Plastic IntroductionDocument12 pagesJournal Plastic IntroductionNiammMbladdushNo ratings yet

- Chemical Admixtures For Concrete: Superplasticizers Özge Andiç Çakır, PHDDocument44 pagesChemical Admixtures For Concrete: Superplasticizers Özge Andiç Çakır, PHDdonjuan4848No ratings yet

- FTIR Spectra and Mechanical Properties of Nano-Sized Calcium Carbonate Reinforced Cross-Linked High Density PolyethyleneDocument3 pagesFTIR Spectra and Mechanical Properties of Nano-Sized Calcium Carbonate Reinforced Cross-Linked High Density PolyethyleneUriel PeñaNo ratings yet

- Estimating Unit Rate for Plastering WorkDocument26 pagesEstimating Unit Rate for Plastering Workfaroukm91No ratings yet

- Concrete StampedDocument28 pagesConcrete StampedOlajide AdedamolaNo ratings yet

- Yanam PSR 2010-11 Book Schedule of RatesDocument869 pagesYanam PSR 2010-11 Book Schedule of RatesSaurabh Kumar SharmaNo ratings yet

- CADANGAN MEMBINA SEBUAH RUMAH PENGAWALDocument20 pagesCADANGAN MEMBINA SEBUAH RUMAH PENGAWALzulNo ratings yet

- Firestop Technician Job DescriptionDocument2 pagesFirestop Technician Job DescriptionHilary TerryNo ratings yet

- 321 00055 PDFDocument0 pages321 00055 PDFA MahmoodNo ratings yet

- DOE Condition Assessment Work Breakdown StructureDocument1 pageDOE Condition Assessment Work Breakdown Structurescribd_spiceNo ratings yet

- Sika Top Seal 107 MSDocument3 pagesSika Top Seal 107 MSTan TounNo ratings yet

- Condensation in Buildings: Prepared By: Zarina Yasmin Hanur HarithDocument19 pagesCondensation in Buildings: Prepared By: Zarina Yasmin Hanur HarithSyafawani SyazyraNo ratings yet

- Medical Device Solutions: Links Science To LifeDocument8 pagesMedical Device Solutions: Links Science To Lifeabhijit_gothoskar6039No ratings yet

- Thermal Conductivity of MaterialDocument7 pagesThermal Conductivity of MaterialPhyu Mar Thein Kyaw0% (1)

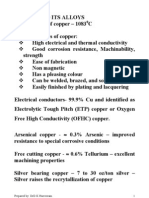

- Copper and It's AlloysDocument5 pagesCopper and It's AlloysReza MortazaviNo ratings yet

- Comparative of BOQ - Finishing ItemDocument202 pagesComparative of BOQ - Finishing Itemanjanepal100% (1)

- Structural Concept For ArchDocument15 pagesStructural Concept For ArchRonie SapadNo ratings yet

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- Halo ODST Armor Torso Part 2 of 5 of ODST ArmorDocument22 pagesHalo ODST Armor Torso Part 2 of 5 of ODST Armorme100% (1)

- TDS PFA Cem Gaurd IndiaDocument8 pagesTDS PFA Cem Gaurd IndiaDamodharNo ratings yet

- K10 GRS 2000Document2 pagesK10 GRS 2000Dilon FernandoNo ratings yet

- Flow Chart of Proto Sample Development in Apparel IndustryDocument22 pagesFlow Chart of Proto Sample Development in Apparel Industrysabber100% (1)

- Apple Rubber O-RingsDocument6 pagesApple Rubber O-RingsKiran Kumar K TNo ratings yet

- A Handbook of Thermal Bridging Details Incorporating Aircrete Blocks - Book 1Document73 pagesA Handbook of Thermal Bridging Details Incorporating Aircrete Blocks - Book 1NeedleandMortar100% (2)

- Aluminum 5083Document2 pagesAluminum 5083razormebackNo ratings yet