Professional Documents

Culture Documents

Concrete Formwork

Uploaded by

shingkeongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Formwork

Uploaded by

shingkeongCopyright:

Available Formats

Concrete Formwork

General Requirements

Safe must hold concrete in place until

cured.

Economical

provide desired shape and surface texture

Formwork usually cost more than the

concrete

Typical formwork

Can be

wood

Steel

Aluminum

Must be braced to withstand load (concrete

weighs 150pcf)

Wall form F 11-18

Double wales used above and below ties to allow

tie to be secured

Also need a spreader to keep forms correct

distance apart

Need to have good bracing at foot of form

Ties F 11-19

Most common can be broken off just inside

concrete allows for patching

Column Forms

Use column clamps for support/bracing

May have windows to making pouring easier

F 11-20

Slabs

F 11- 21 -> 11-25

Construction Practices

Forms need tight joints

Forms need to be aligned and checked for

alignment during pour

Dont forget uplift on some types of forms

Dont drop concrete more than 5

Dont vibrate previously poured concrete too

deeply could cause form failure

Carefully remove forms dont want surface

damage

Expansion and control joints

Permit differential movement in concrete

shapes

Concrete shrinkage, temperature change,

moisture change, settlement

Isolate interior columns from floor slab cut

around column

Formwork safety

Pg 321

Reinforcing Steel

Reinforcing bars

Usually deformed (manufactured with ridges

to increase bond with concrete)

Can be plain or epoxy coated

Sized by 1/8

th

inch and strength of steel

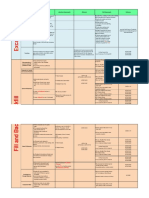

T 11-1, F 11-28

Reinforcing Steel

Welded wire fabric

Common for slabs

Smooth or deformed wire

WWF is identifier

WWF 6x6-4.0x4.0 is a welded wire fabric with

6 inch spacing longitudinally and transversely

made of W4 size (0.04 x section area) wire

Spirals (for columns)

3 standard sizes 3/8 inch, inch, 5/8 inch

diameter rods

Sprial diameters (outside to outside) 12

minimum to 33 max

Pitch from 1.75 3.25 (distance from center

to center of rod)

Placing Reinforcing

Rebar goes in areas of tension

F 11-29

Need to protect rebar from corrosion fire

and weather

Pg 325 gives min cover

Minimum clear distance between parallel bars

in columns = 1.5 or 1.5 x max aggregate size

For other shapes 1 or 1.333 x max aggregate

size

Placing Reinforcing

Rebars kept in place by ties

F 11-30, 11-31

QC

Common deficiencies

Pg 329

Inspection and Testing

Usually concrete is a fast paced activity

Need to inspect product from stockpile to

placement and then test for strength, air

entrainment, beam flexure

You might also like

- Astm A884-A884m-02 Specs For Epoxy-Coated Steel WireDocument6 pagesAstm A884-A884m-02 Specs For Epoxy-Coated Steel WireCharwin PicaoNo ratings yet

- Potable Water Thrust Blocks Construction ChecklistDocument1 pagePotable Water Thrust Blocks Construction ChecklistJabinNo ratings yet

- ASTMDocument7 pagesASTMMarko's Brazon'No ratings yet

- THE Card: R E A LDocument4 pagesTHE Card: R E A LMohamed Ahmed RezkNo ratings yet

- Gabion Wall Installation GuideDocument5 pagesGabion Wall Installation GuideJoel KomaNo ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- C - 1 Hydrography Manual M-13Document46 pagesC - 1 Hydrography Manual M-13Zannatul NayemaNo ratings yet

- Astm - D 3754-04Document14 pagesAstm - D 3754-04Wen ZhuNo ratings yet

- Excavation and Fill Method Statement SummaryDocument12 pagesExcavation and Fill Method Statement Summary한상호No ratings yet

- 0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentDocument4 pages0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentRA SamsonNo ratings yet

- CE 101 MODULE 1 History of Civil EngineeringDocument10 pagesCE 101 MODULE 1 History of Civil EngineeringStudy ReviewNo ratings yet

- Are They Pour Lines or Cold Joints - tcm45-348413Document4 pagesAre They Pour Lines or Cold Joints - tcm45-348413محمد كاشف جاويدNo ratings yet

- Preprufe 300R & 160R PDFDocument6 pagesPreprufe 300R & 160R PDForlandomcortezNo ratings yet

- PPQCDocument14 pagesPPQCখালিদহাসানNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- Section 04 Concrete WorksDocument32 pagesSection 04 Concrete WorksMarvin MessiNo ratings yet

- MST Leak Test GRPDocument2 pagesMST Leak Test GRPmohd hyderNo ratings yet

- C 1047 - 99 QzewndcDocument3 pagesC 1047 - 99 QzewndcGarcia ManuelNo ratings yet

- Concrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDocument4 pagesConcrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDarwin Darmawan100% (1)

- Installation Manual - Chain Link FenceDocument2 pagesInstallation Manual - Chain Link FenceChase GietterNo ratings yet

- Upgrade GCs Water Facilities and Mitigation Works Technical SpecificationDocument49 pagesUpgrade GCs Water Facilities and Mitigation Works Technical SpecificationahmadNo ratings yet

- Al Bilad Factory for HDPE and PP PipesDocument53 pagesAl Bilad Factory for HDPE and PP PipesQuerubin R Yolando Jr.No ratings yet

- Elec SpecsDocument32 pagesElec SpecsjewdNo ratings yet

- ANSI-SDI A250.8 Overview PDFDocument8 pagesANSI-SDI A250.8 Overview PDFYel DGNo ratings yet

- Fiberglass Manholes: Sanitary Sewer LinesDocument10 pagesFiberglass Manholes: Sanitary Sewer LinesshagogalNo ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- WQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers WorksDocument68 pagesWQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers Worksmuhammad.younisNo ratings yet

- Precast Concrete Design and Construction RequirementsDocument5 pagesPrecast Concrete Design and Construction RequirementsNino Celso Astillero100% (2)

- Concrete Work 1. Standard and Codes of PracticeDocument28 pagesConcrete Work 1. Standard and Codes of PracticeArka ShahRilNo ratings yet

- Basf Masterlife Ci 222 TdsDocument2 pagesBasf Masterlife Ci 222 TdsAnonymous ouZFaSBRNo ratings yet

- Screeding WorksDocument1 pageScreeding WorksCindy AmyzaNo ratings yet

- L4-QAT-087C Method Statement For Patch Repair WorkDocument10 pagesL4-QAT-087C Method Statement For Patch Repair WorkrajaNo ratings yet

- Method Statement of Bored Piles 21Document40 pagesMethod Statement of Bored Piles 21Dharma Pratap LamgadeNo ratings yet

- DriscoPlex 4100 HDPEDocument16 pagesDriscoPlex 4100 HDPEMarquinho LsNo ratings yet

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDocument2 pagesSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNo ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForThurain Aung KyawNo ratings yet

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarmanNo ratings yet

- Astm D713Document3 pagesAstm D713LIN SONGNo ratings yet

- BS 5572Document10 pagesBS 5572Andrew MutuaNo ratings yet

- Saep 35Document8 pagesSaep 35Anonymous 4IpmN7OnNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 TdsVijayaraghavan Srinivasamurthi100% (1)

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanNo ratings yet

- Steel Erection 6512Document63 pagesSteel Erection 6512brenstagNo ratings yet

- Athletic Equipment InstallationDocument5 pagesAthletic Equipment InstallationuddinnadeemNo ratings yet

- Electrofusion WeldingDocument3 pagesElectrofusion Weldingmaheshmalaichamy007No ratings yet

- HDPE Pipe and Fittings PDFDocument9 pagesHDPE Pipe and Fittings PDFCris BandaNo ratings yet

- FE Civil CBT Specs With RangesDocument4 pagesFE Civil CBT Specs With RangesSanam AfreenNo ratings yet

- The Repair OptionDocument4 pagesThe Repair OptionMAGUNAMNo ratings yet

- 6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueDocument9 pages6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueMr A. M. OlajumokeNo ratings yet

- Feasibility of Manufacturing Silt Curtains in IndiaDocument3 pagesFeasibility of Manufacturing Silt Curtains in IndiaarvindkaushikNo ratings yet

- Safe concreting methodsDocument11 pagesSafe concreting methodsJustin Ranjit100% (1)

- Producing Corrugated Pipes 200-800mmDocument24 pagesProducing Corrugated Pipes 200-800mmdirect2aakashNo ratings yet

- How To Select A Heat Shrink SleeveDocument2 pagesHow To Select A Heat Shrink SleeveLava SatNo ratings yet

- Sewerage and WWTP measures in the city of Korca“ project testing proceduresDocument9 pagesSewerage and WWTP measures in the city of Korca“ project testing proceduresJohnny RamboNo ratings yet

- Form WorkDocument64 pagesForm WorkAnjali ShahNo ratings yet

- Formwork 150318073913 Conversion Gate01Document59 pagesFormwork 150318073913 Conversion Gate01mit rami100% (1)

- Formwor K: A Study of Its Various Types, Materials AND Construction TechniquesDocument60 pagesFormwor K: A Study of Its Various Types, Materials AND Construction TechniquesDeep GuptaNo ratings yet

- Plastic Shrinkage Cracking (BPS)Document36 pagesPlastic Shrinkage Cracking (BPS)shingkeongNo ratings yet

- The Role of Composite Joints On The Performance of Steel-Framed Buildings in FireDocument27 pagesThe Role of Composite Joints On The Performance of Steel-Framed Buildings in FireshingkeongNo ratings yet

- Traditional Wood JointsDocument35 pagesTraditional Wood JointsshingkeongNo ratings yet

- Structures and ForcesDocument104 pagesStructures and ForcesshingkeongNo ratings yet

- Straw Tubes and Hall D: Zebulun Krahn Carnegie Mellon UniversityDocument20 pagesStraw Tubes and Hall D: Zebulun Krahn Carnegie Mellon UniversityshingkeongNo ratings yet

- Sub Structure FoundationDocument32 pagesSub Structure FoundationshingkeongNo ratings yet

- Ultrasonic Bolt Tension MeasurementDocument8 pagesUltrasonic Bolt Tension MeasurementshingkeongNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Drainage DesignDocument40 pagesDrainage DesignshingkeongNo ratings yet

- Soil EngineeringDocument19 pagesSoil EngineeringpepitNo ratings yet

- Structural Considerations BridgesDocument47 pagesStructural Considerations BridgesshingkeongNo ratings yet

- Drinking Water ContaminationDocument10 pagesDrinking Water ContaminationshingkeongNo ratings yet

- Site Investigation For Foundation DesignDocument6 pagesSite Investigation For Foundation DesignshingkeongNo ratings yet

- 9911511Document7 pages9911511Bhaskar BhatiaNo ratings yet

- Hydraulics and PneumaticDocument112 pagesHydraulics and Pneumaticsurendar100% (2)

- Crossing StructuresDocument14 pagesCrossing StructuresshingkeongNo ratings yet

- Introduction Thermal FluidDocument17 pagesIntroduction Thermal FluidshingkeongNo ratings yet

- Steel Dowel Bar Corrosion in Concrete Pavement : by Accelerated TestDocument39 pagesSteel Dowel Bar Corrosion in Concrete Pavement : by Accelerated TestshingkeongNo ratings yet

- Analysis of Failures in Timber StructuresDocument28 pagesAnalysis of Failures in Timber StructuresshingkeongNo ratings yet

- Design of Multi Stories BuildingDocument43 pagesDesign of Multi Stories BuildingshingkeongNo ratings yet

- Design of Steel Structure - Steel Design Tension MembersDocument24 pagesDesign of Steel Structure - Steel Design Tension MembersshingkeongNo ratings yet

- Alaska Concrete SummitDocument49 pagesAlaska Concrete SummitshingkeongNo ratings yet

- Bolts in TensionDocument20 pagesBolts in TensionshingkeongNo ratings yet

- Design of Steel Structure - Connection DesignDocument33 pagesDesign of Steel Structure - Connection DesignshingkeongNo ratings yet

- Channel DesignDocument44 pagesChannel DesignshingkeongNo ratings yet

- Channel DesignDocument44 pagesChannel DesignshingkeongNo ratings yet

- Assessment of Prestressing Force by Proof LoadDocument17 pagesAssessment of Prestressing Force by Proof LoadshingkeongNo ratings yet

- Construction TechnologyDocument55 pagesConstruction TechnologyshingkeongNo ratings yet

- Alternative Bidding West VirginiaDocument20 pagesAlternative Bidding West VirginiashingkeongNo ratings yet

- Concrete StructuresDocument28 pagesConcrete StructuresshingkeongNo ratings yet

- Wall Finishes PPT (1) (1) Taniya PDFDocument15 pagesWall Finishes PPT (1) (1) Taniya PDFRajaNo ratings yet

- Assignment IDocument2 pagesAssignment IPratik SolankiNo ratings yet

- Design of Continuous Roof BeamDocument8 pagesDesign of Continuous Roof BeamJohn Harold CastroNo ratings yet

- Sustainable concrete: a key material for constructionDocument13 pagesSustainable concrete: a key material for constructionJiabin LiNo ratings yet

- Attachment 3323Document876 pagesAttachment 3323Mark ReinhardtNo ratings yet

- Building Form and Orientation For Sun and WindDocument3 pagesBuilding Form and Orientation For Sun and Windsusmita sethi0% (1)

- East Meets West PHC Dharmapuri Case StudyDocument17 pagesEast Meets West PHC Dharmapuri Case StudySAHAYA THARINI F0% (1)

- Cosh41 AttachmentDDocument3 pagesCosh41 AttachmentDajmaluetNo ratings yet

- Lewis Constructional Covering Floors PDFDocument2 pagesLewis Constructional Covering Floors PDFVengatesh NJNo ratings yet

- List of SKSD Construction ProjectsDocument1 pageList of SKSD Construction ProjectsStatesman JournalNo ratings yet

- Earthquake Resistant Design of Structures: September 2013Document36 pagesEarthquake Resistant Design of Structures: September 2013Er. Kuldeep Singh NayakNo ratings yet

- Final Version TORDocument6 pagesFinal Version TORMary Joy RuilesNo ratings yet

- LSD Doubly Reinforced Simple Supported BeamDocument10 pagesLSD Doubly Reinforced Simple Supported BeamRamilArtates100% (1)

- QCP Barangonbong RevisedDocument44 pagesQCP Barangonbong Revisedruzsi07No ratings yet

- Is 1661 1972 PDFDocument33 pagesIs 1661 1972 PDFPrasanna S KulkarniNo ratings yet

- PRAGMATIC ADAPTIVE REUSE OF A HISTORIC BUILDINGDocument22 pagesPRAGMATIC ADAPTIVE REUSE OF A HISTORIC BUILDINGArul Dhas100% (1)

- Project Cost Estimate (CARPORT) PDFDocument4 pagesProject Cost Estimate (CARPORT) PDFJMike P. FernandezNo ratings yet

- An Overview of The Uniform Building By-Laws, 1984 & The Amendments 2007 (Part 4 - 5)Document9 pagesAn Overview of The Uniform Building By-Laws, 1984 & The Amendments 2007 (Part 4 - 5)Ar. Meor Wazir Zul'AidinNo ratings yet

- Balayag Manok, ValenciaDocument91 pagesBalayag Manok, ValenciajayNo ratings yet

- 2500 UT Unitwall System - A PDFDocument24 pages2500 UT Unitwall System - A PDFerickcastillo1No ratings yet

- Building Economics: Infosys, HyderabadDocument8 pagesBuilding Economics: Infosys, HyderabadIshita Bhardwaj0% (1)

- Housing Management of Cattle and BuffaloDocument13 pagesHousing Management of Cattle and BuffaloTlm BhopalNo ratings yet

- NVC in Block Laying and Concreting CurriculumDocument84 pagesNVC in Block Laying and Concreting Curriculumkhalid abdulazizNo ratings yet

- Oxley Bizhub Singapore - Ebrochure & Floor PlansDocument27 pagesOxley Bizhub Singapore - Ebrochure & Floor PlansRichard Sng100% (1)

- Air Testing Formats (Banas Dairy)Document11 pagesAir Testing Formats (Banas Dairy)ghazi4uNo ratings yet

- Steel Roof Trusses 2Document35 pagesSteel Roof Trusses 2ASRNo ratings yet

- Building Permit Register Jan To Dec 2015Document462 pagesBuilding Permit Register Jan To Dec 2015Oz Ree100% (1)

- Uiuc CDDocument102 pagesUiuc CDirvingsaavNo ratings yet

- Plumbing & Sanitary BOQDocument12 pagesPlumbing & Sanitary BOQsooricivil0% (1)

- Raised Floor SystemDocument17 pagesRaised Floor SystemZehra JabeenNo ratings yet