Professional Documents

Culture Documents

DSO Sewage Treatment Project Presentation

Uploaded by

vipin_nair01Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSO Sewage Treatment Project Presentation

Uploaded by

vipin_nair01Copyright:

Available Formats

Mechanical Team

Presentations on

Domestic Supply Obligation (DSO)

Project

SEWAGE TREATMENT

UNITS

BY

ADELAYO OLUFEMI ORI YOMI

Waste is often categorised into Industrial and Domestic waste

In Industries, Homes and on worksites, as long as there is work being done,

waste is generated.

Sewage treatment is the process of removing contaminants from

wastewater and household sewage, both runoff (effluents) and

domestic. It includes physical, chemical, and biological processes to

remove physical, chemical and biological contaminants. Its objective is

to produce an environmentally safe fluid waste stream (or treated

effluent) and a solid waste (or treated sludge) suitable for disposal or

reuse (usually as farm fertilizer). Using advanced technology it is now

possible to re-use sewage effluent for drinking water, although

Singapore is the only country to implement such technology on a

production scale.

Domestic waste can be further divided into grey and black water. The need to

effectively treat the domestic waste generate in such a way that it will not

negatively affect the environment, necessitates the need for the treatment of the

sewage before it is then properly disposed.

Where does it all go!

Where does the

water from the

washer go?

When you flush the

toilet where does

the contents go?

By gravity flow, the waste is on its way

to your local wastewater treatment plant!

Waste Water Treatment

Here's a step-by-step guide describing what happens at each stage of the

treatment process and how pollutants are removed to help keep our waterways

clean.

Wastewater Treatment Diagram

The Primary Treatment Process

Screening: Wastewater

entering the treatment

plant includes items like

wood, rocks, and even

dead animals. Unless

they are removed, they

could cause problems

later in the treatment

process. Most of these

materials are sent to a

landfill.

Pumping: The wastewater

system relies on the force of

gravity to move sewage from

your home to the treatment

plant. So wastewater-

treatment plants are located

on low ground, often near a

river into which treated water

can be released. If the plant is

built above the ground level,

the wastewater has to be

pumped up to the aeration

tanks. From here on, gravity

takes over to move the

wastewater through the

treatment process.

Aerating

One of the first steps that a water

treatment facility can do is to just

shake up the sewage and expose

it to air. This causes some of the

dissolved gases (such as hydrogen

sulfide, which smells like rotten

eggs) that taste and smell bad to

be released from the water.

Wastewater enters a series of

long, parallel concrete tanks. Each

tank is divided into two sections.

In the first section, air is pumped

through the water.

As organic matter decays, it uses

up oxygen. Aeration replenishes

the oxygen. Bubbling oxygen

through the water also keeps the

organic material suspended while

it forces 'grit' (coffee grounds,

sand and other small, dense

particles) to settle out. Grit is

pumped out of the tanks and

taken to landfills.

Removing Sludge

Wastewater then enters the

second section or sedimentation

tanks. Here, the sludge (the

organic portion of the sewage)

settles out of the wastewater and

is pumped out of the tanks. Some

of the water is removed in a step

called thickening and then the

sludge is processed in large tanks

called digesters.

Removing Scum

As sludge is settling to the bottom

of the sedimentation tanks, lighter

materials are floating to the

surface. This 'scum' includes

grease, oils, plastics, and soap.

Slow-moving rakes skim the scum

off the surface of the wastewater.

Scum is thickened and pumped to

the digesters along with the

sludge.

Killing Bacteria

Finally, the wastewater flows into a 'chlorine contact' tank, where

the chemical chlorine is added to kill bacteria, which could pose a

health risk, just as is done in swimming pools. The chlorine is mostly

eliminated as the bacteria are destroyed, but sometimes it must be

neutralized by adding other chemicals. This protects fish and other

marine organisms, which can be harmed by the smallest amounts of

chlorine.

The treated water (called effluent) is then discharged to a local river

or the ocean

Sewage Treatment on DSO

The Sewage Treatment Package on the DSO will

be designed and constructed by the vendor

Red Fox

DSO Sewage Treatment Package

2 Units in number (one each

on GGCP & LQP)

Sewage Holding and

Processing capacity of 50

gallons

Service Life of 20 years

Aeration Tank (24 hours

retention time)

Chlorine contact chamber

Skimmers

Cathodic Protection

The sewage disposal system

shall be a biological, activated

sludge, extended-aeration

sewage treatment plant by the

data sheets for discharge into

the ocean

The disposal system shall be

constructed in a compact

manner with adequate space

for access and maintenance of

all system components without

removing any major assembly.

The treatment plant proper

shall consist of shall consist of

an aeration tank, setting

chamber, and chlorine contact

chamber mounted on a single

skid.

Waste Water P & ID

Sewage Treatment GAD

THANK YOU FOR LISTENING

You might also like

- Sewage Treatment PlantDocument34 pagesSewage Treatment PlantJohn Paul Paro100% (3)

- Ankit Akela Minor ProjectDocument34 pagesAnkit Akela Minor ProjectAnkit TuranNo ratings yet

- Waste WaterDocument63 pagesWaste Waterashe zinabNo ratings yet

- Waste Water Treatment in 40 CharactersDocument6 pagesWaste Water Treatment in 40 Charactersstylish eagle100% (1)

- Visit ReportDocument9 pagesVisit Reportrohit Sharma100% (1)

- Loading S Calculations by Dr. Ghaida Abu Rumman enDocument36 pagesLoading S Calculations by Dr. Ghaida Abu Rumman ensauroNo ratings yet

- 10 Cum - DayDocument5 pages10 Cum - DayAbhijit MondalNo ratings yet

- Reaction Paper "Advanced Water Treatment"Document1 pageReaction Paper "Advanced Water Treatment"CharisseElaineDionisioNo ratings yet

- Dairy Waste Water Treatment by BiofilterDocument29 pagesDairy Waste Water Treatment by BiofilterShah Rajendra100% (1)

- Activated SludgeDocument27 pagesActivated SludgeMukesh JagaNo ratings yet

- Disinfection Methods for Water TreatmentDocument6 pagesDisinfection Methods for Water TreatmentAriff JasniNo ratings yet

- MBBR Process ReportDocument55 pagesMBBR Process ReportAbhisek BhattacharyaNo ratings yet

- Concept of Zero DischargeDocument4 pagesConcept of Zero DischargeShesharam Chouhan67% (3)

- Lesson Plan: How Do We Clean Polluted Water?Document15 pagesLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNo ratings yet

- MA - LFP Submersible MixerDocument12 pagesMA - LFP Submersible MixerSid Esterico SestosoNo ratings yet

- Chapter 4 StudentDocument48 pagesChapter 4 StudentMaster-s Hero-sNo ratings yet

- What Is An ETP PlantDocument12 pagesWhat Is An ETP PlantrohitNo ratings yet

- Decentralized Wastewater Treatment Highlights BrochureDocument20 pagesDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNo ratings yet

- Advance Digestion Water TreatmentDocument2 pagesAdvance Digestion Water TreatmentRashesh ShahNo ratings yet

- 03 Conventional Water TreatmentDocument80 pages03 Conventional Water Treatmentbksri1239561No ratings yet

- Design of Arraba Wastewater Treatment PlantDocument47 pagesDesign of Arraba Wastewater Treatment PlantMOHAMMED ABBAS NAJI MAALANo ratings yet

- Rapid Sand FiltrationDocument16 pagesRapid Sand FiltrationNurul ShafinazNo ratings yet

- Waste Management OAUDocument9 pagesWaste Management OAUakangbe bolajiNo ratings yet

- Stormwater Drainage DesignDocument17 pagesStormwater Drainage DesignAenan BashirNo ratings yet

- EE-2 Mini Project ReportDocument7 pagesEE-2 Mini Project Report63GANESH SINGHCIVILNo ratings yet

- Sewerage and Sewage Treatment - 2014 - Solutions For End Semester ExaminationDocument16 pagesSewerage and Sewage Treatment - 2014 - Solutions For End Semester ExaminationDr. Akepati Sivarami ReddyNo ratings yet

- OPERATION & MAINTENANCE MANUAL HIGHLIGHTSDocument49 pagesOPERATION & MAINTENANCE MANUAL HIGHLIGHTSsudhakarrajam2002100% (1)

- Journal of Water Process Engineering: SciencedirectDocument8 pagesJournal of Water Process Engineering: SciencedirectOmar GameelNo ratings yet

- 12 - Rotating Biological Contactor-ProcessDocument55 pages12 - Rotating Biological Contactor-ProcessMohammed Barni100% (1)

- Water TreatmentDocument2 pagesWater TreatmentJumasonicNo ratings yet

- Attached Growth Reactors Trickling Filters ExplainedDocument31 pagesAttached Growth Reactors Trickling Filters ExplainedJon Bisu Debnath100% (1)

- WWTPDocument47 pagesWWTPHar Ley QuinnNo ratings yet

- Conventional Waste Water TreatmentsDocument44 pagesConventional Waste Water Treatmentsakhilt29100% (4)

- Tertiary TreatmentDocument45 pagesTertiary TreatmentsunitaudayNo ratings yet

- Introduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationDocument33 pagesIntroduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationAgus WitonoNo ratings yet

- Water Treatment ProcessesDocument18 pagesWater Treatment ProcessesClaude Geoffrey escanillaNo ratings yet

- LECTURE 11 - Conventional Water Treatment Facility2014Document51 pagesLECTURE 11 - Conventional Water Treatment Facility2014Kaaviyan thirunyanamNo ratings yet

- The STP Guide-Design, Operation and MaintenanceDocument74 pagesThe STP Guide-Design, Operation and MaintenanceRajesh ShenoyNo ratings yet

- AOPs A Critical Review PDFDocument54 pagesAOPs A Critical Review PDFM S MahtabNo ratings yet

- Lecture 3 Screening and Grit ChambersDocument11 pagesLecture 3 Screening and Grit ChambersAs MihNo ratings yet

- Trickling FilterDocument34 pagesTrickling FilterDr. Akepati Sivarami Reddy100% (9)

- 3RD ModuleDocument145 pages3RD ModuleNiveditha VinodNo ratings yet

- Characteristics of Sewage PDFDocument13 pagesCharacteristics of Sewage PDFUtsav SharmaNo ratings yet

- Development of Advanced Water Treatment Using Microbubbles - Pan Li - 2006Document149 pagesDevelopment of Advanced Water Treatment Using Microbubbles - Pan Li - 2006cristian muozNo ratings yet

- Design of Sewage Treatment Plants CourseDocument56 pagesDesign of Sewage Treatment Plants CourseChanel100% (1)

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsDocument34 pagesWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanNo ratings yet

- Active Sludge PDFDocument8 pagesActive Sludge PDFDark_KiroNo ratings yet

- Design of Sewage Treatment Plant For PKCDocument42 pagesDesign of Sewage Treatment Plant For PKCMahesh NalawadeNo ratings yet

- Stabilization PondsDocument25 pagesStabilization PondsDevendra SharmaNo ratings yet

- Sanitary Sewer Design and Modeling WorksDocument117 pagesSanitary Sewer Design and Modeling WorksNassif Abi AbdallahNo ratings yet

- Iii. Preliminary Unit Operations and Processes: Water TreatmentDocument56 pagesIii. Preliminary Unit Operations and Processes: Water Treatmentasya rüyasıNo ratings yet

- Advanced Activated Sludge ProcessDocument5 pagesAdvanced Activated Sludge ProcessDileep C DileepNo ratings yet

- Aeration System in WWTPDocument10 pagesAeration System in WWTPashokNo ratings yet

- Water and Wastewater EngineeringDocument6 pagesWater and Wastewater EngineeringFaris AsriNo ratings yet

- High Rate Bio Trickling FiltersDocument11 pagesHigh Rate Bio Trickling FiltersFriends of the Atlantic Coast Watch NewsletNo ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- A Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFDocument12 pagesA Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFtebo8teboNo ratings yet

- Daily Prayers and Rituals CollectionDocument92 pagesDaily Prayers and Rituals Collectionagrocel_bhv5591No ratings yet

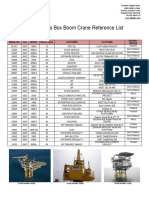

- Nautilus Box Boom Crane Reference ListDocument6 pagesNautilus Box Boom Crane Reference Listvipin_nair01100% (2)

- Basic Rigging Work BookDocument45 pagesBasic Rigging Work BookJohn Henry Sinurat100% (1)

- The Elements of The Machine DesignDocument13 pagesThe Elements of The Machine DesignguhanvishnuNo ratings yet

- Daily Prayers and Rituals CollectionDocument92 pagesDaily Prayers and Rituals Collectionagrocel_bhv5591No ratings yet

- AIA-Checklist For InspectionsDocument9 pagesAIA-Checklist For Inspectionsvipin_nair01No ratings yet

- Stdxi Voc Ema em 2 PDFDocument248 pagesStdxi Voc Ema em 2 PDFBpdplanning MadhuconNo ratings yet

- Article - Metric System & SpecificationsDocument5 pagesArticle - Metric System & Specificationsjchristoe2613No ratings yet

- How Savings Bank Interest is Calculated and Taxed in IndiaDocument2 pagesHow Savings Bank Interest is Calculated and Taxed in Indiavipin_nair01No ratings yet

- Interview With Dr. PrakashDocument4 pagesInterview With Dr. Prakashvipin_nair01No ratings yet

- AlignmentDocument48 pagesAlignmentvipin_nair01No ratings yet

- Cook BookDocument6 pagesCook Bookvipin_nair01No ratings yet

- Reverse Dial-Indicator-Alignment-Procedure PDFDocument4 pagesReverse Dial-Indicator-Alignment-Procedure PDFamirthraj74No ratings yet

- How Savings Bank Interest is Calculated and Taxed in IndiaDocument2 pagesHow Savings Bank Interest is Calculated and Taxed in Indiavipin_nair01No ratings yet

- Guia de Salario Petroleo y Gas Hays - 920901Document36 pagesGuia de Salario Petroleo y Gas Hays - 920901Javier CastroNo ratings yet

- Mecanical CompletionDocument1 pageMecanical Completionvipin_nair01No ratings yet

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Design of Offshore StructuresDocument11 pagesDesign of Offshore StructuresInayath Hussain100% (1)

- German Language CourseDocument210 pagesGerman Language Course42099% (71)

- Topic - Beam-Columns PDFDocument17 pagesTopic - Beam-Columns PDFelixnzNo ratings yet

- Classification of SteelsDocument28 pagesClassification of Steelsvipin_nair01No ratings yet

- MS Project 2007 Tutorial-Final VersionDocument61 pagesMS Project 2007 Tutorial-Final Versionlimmil100% (1)

- Air Conditioning Duct Design-Lecture 38Document20 pagesAir Conditioning Duct Design-Lecture 38Mrityunjay TiwariNo ratings yet

- FuelsDocument2 pagesFuelsvipin_nair01No ratings yet

- Mechanical Drawing Problems RawDocument224 pagesMechanical Drawing Problems Rawvipin_nair01No ratings yet

- Final Feasibility Study Report IGBC Green Homes Villa Sector 44 NoidaDocument41 pagesFinal Feasibility Study Report IGBC Green Homes Villa Sector 44 NoidaHariharanNo ratings yet

- Green Gender Gap ReportDocument23 pagesGreen Gender Gap ReportIvini FerrazNo ratings yet

- PowerPoint - Reduce Reuse and RecycleDocument7 pagesPowerPoint - Reduce Reuse and RecycleRekha MoghaNo ratings yet

- Identification and Assessment of Environment Aspects and OH & S HazardDocument4 pagesIdentification and Assessment of Environment Aspects and OH & S Hazardx_imran7417No ratings yet

- Earth's Four Spheres: Lithosphere, Hydrosphere, Biosphere & AtmosphereDocument3 pagesEarth's Four Spheres: Lithosphere, Hydrosphere, Biosphere & AtmosphereFerlynne Marie BernardinoNo ratings yet

- Contract Risk Checklist: Initiate ReviewDocument3 pagesContract Risk Checklist: Initiate ReviewABINOU OUNIBA100% (1)

- The Cycles Questions Rewritten From Original WorksheetDocument2 pagesThe Cycles Questions Rewritten From Original WorksheetAmyNo ratings yet

- Ap Biology Chapter 40Document16 pagesAp Biology Chapter 40api-392375614No ratings yet

- Introduction To Ramsar and WetlandsDocument4 pagesIntroduction To Ramsar and WetlandsNitish ChiniaNo ratings yet

- Speciation Extinction WorksheetDocument1 pageSpeciation Extinction Worksheetapi-256236481No ratings yet

- Flora and Fauna of Jammu and Kashmir: Related TopicsDocument3 pagesFlora and Fauna of Jammu and Kashmir: Related TopicsAxcNo ratings yet

- Lake Limboto in Climate ChangeDocument3 pagesLake Limboto in Climate ChangedonskayNo ratings yet

- Workshop E&CDocument2 pagesWorkshop E&CvinomalaiNo ratings yet

- Heart of Nature: Norasma Yasimin BT SulimanDocument13 pagesHeart of Nature: Norasma Yasimin BT SulimanMiliNo ratings yet

- Malaysia IWRMDocument5 pagesMalaysia IWRMharras lordNo ratings yet

- LinkingLandscapes 10 16 19Document30 pagesLinkingLandscapes 10 16 19Huaying ZhugeNo ratings yet

- S7 Q2 Summative Test 4Document5 pagesS7 Q2 Summative Test 4Raniel LacuarinNo ratings yet

- PrefaceDocument549 pagesPrefaceGlasst Innovacion 2019No ratings yet

- CSR and PhilanthropyDocument8 pagesCSR and PhilanthropyAditi BishtNo ratings yet

- The World Climate Refers To The LongDocument2 pagesThe World Climate Refers To The LongTg GhabhyNo ratings yet

- ADB - Camp 4Document129 pagesADB - Camp 4TanvirH.ChowdhuryNo ratings yet

- Developing Sanitary LandfillsDocument3 pagesDeveloping Sanitary LandfillsChristine Joy BuenNo ratings yet

- What Is A FloraDocument15 pagesWhat Is A FloraDr-Abdul Hameed LanjwaniNo ratings yet

- OrganicFertilizer TypeProductionandEnivronmentalImpactDocument290 pagesOrganicFertilizer TypeProductionandEnivronmentalImpactAnonymous Wc69e8wpn100% (3)

- New Approaches For Evaluation of Soil HealthDocument7 pagesNew Approaches For Evaluation of Soil Healthasep mulyonoNo ratings yet

- Pedodiversity and Pedocyclicity - Soil in Space and TimeDocument281 pagesPedodiversity and Pedocyclicity - Soil in Space and Timecozma_120% (1)

- 1-Flood Control Strategies (Structural Mitigation Measures)Document9 pages1-Flood Control Strategies (Structural Mitigation Measures)Bondoc, Miles Jerome Z.No ratings yet

- Management Accountant June 2020Document124 pagesManagement Accountant June 2020ABC 123No ratings yet

- Lawn and Landscape Watering Schedule - 201905201618099144Document2 pagesLawn and Landscape Watering Schedule - 201905201618099144dragos.gaitanaruNo ratings yet

- Eumind Waste ManagementDocument23 pagesEumind Waste Managementapi-440622270No ratings yet