Professional Documents

Culture Documents

Chap011 - Inventory Management

Uploaded by

AgentSkySkyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chap011 - Inventory Management

Uploaded by

AgentSkySkyCopyright:

Available Formats

11-1

Inventory Management

Operations Management

William J. Stevenson

8th edition

11-2

Inventory Management

CHAPTER

11

Inventory

Management

McGraw-Hill/Irwin

Operations Management, Eighth Edition, by William J. Stevenson

Copyright 2005 by The McGraw-Hill Companies, Inc. All rights

11-3

Inventory Management

Inventory: a stock or store of goods

Dependent Demand

C(2)

B(4)

D(2)

Independent Demand

E(1)

D(3)

F(2)

Independent demand is uncertain.

Dependent demand is certain.

11-4

Inventory Management

Types of Inventories

Raw materials & purchased parts

Partially completed goods called

work in progress

Finished-goods inventories

(manufacturing firms)

or merchandise

(retail stores)

11-5

Inventory Management

Types of Inventories (Contd)

Replacement parts, tools, & supplies

Goods-in-transit to warehouses or customers

11-6

Inventory Management

Functions of Inventory

To meet anticipated demand

To smooth production requirements

To decouple operations

To protect against stock-outs

11-7

Inventory Management

Functions of Inventory (Contd)

To take advantage of order cycles

To help hedge against price increases

To permit operations

To take advantage of quantity discounts

11-8

Inventory Management

Objective of Inventory Control

To achieve satisfactory levels of customer

service while keeping inventory costs within

reasonable bounds

Level of customer service

Costs of ordering and carrying inventory

11-9

Inventory Management

Effective Inventory Management

A system to keep track of inventory

A reliable forecast of demand

Knowledge of lead times

Reasonable estimates of

Holding costs

Ordering costs

Shortage costs

A classification system

11-10 Inventory Management

Inventory Counting Systems

Periodic System

Physical count of items made at periodic

intervals

Perpetual Inventory System

System that keeps track

of removals from inventory

continuously, thus

monitoring

current levels of

each item

11-11

Inventory Management

Inventory Counting Systems (Contd)

Two-Bin System - Two containers of

inventory; reorder when the first is empty

Universal Bar Code - Bar code

printed on a label that has

information about the item

to which it is attached

0

214800 232087768

11-12 Inventory Management

Key Inventory Terms

Lead time: time interval between ordering

and receiving the order

Holding (carrying) costs: cost to carry an

item in inventory for a length of time,

usually a year

Ordering costs: costs of ordering and

receiving inventory

Shortage costs: costs when demand exceeds

supply

11-13 Inventory Management

ABC Classification System

Figure 11.1

Classifying inventory according to some

measure of importance and allocating control

efforts accordingly.

A - very important

B - mod. important

C - least important

High

Annual

$ value

of items

A

B

C

Low

Few

Many

Number of Items

11-14 Inventory Management

Cycle Counting

A physical count of items in inventory

Cycle counting management

How much accuracy is needed?

When should cycle counting be performed?

Who should do it?

11-15 Inventory Management

Economic Order Quantity Models

Economic order quantity model

Economic production model

Quantity discount model

11-16 Inventory Management

Assumptions of EOQ Model

Only one product is involved

Annual demand requirements known

Demand is even throughout the year

Lead time does not vary

Each order is received in a single delivery

There are no quantity discounts

11-17 Inventory Management

The Inventory Cycle

Figure 11.2

Q

Quantity

on hand

Profile of Inventory Level Over Time

Usage

rate

Reorder

point

Receive

order

Place Receive

order order

Lead time

Place Receive

order order

Time

11-18 Inventory Management

Total Cost

Annual

Annual

Total cost = carrying + ordering

cost

cost

TC =

Q

H

2

DS

Q

11-19 Inventory Management

Cost Minimization Goal

Figure 11.4C

Annual Cost

The Total-Cost Curve is U-Shaped

Q

D

TC H S

2

Q

Ordering Costs

QO (optimal order quantity)

Order Quantity

(Q)

11-20 Inventory Management

Deriving the EOQ

Using calculus, we take the derivative of the

total cost function and set the derivative

(slope) equal to zero and solve for Q.

Q OPT =

2DS

=

H

2(Annual Demand)(Order or Setup Cost)

Annual Holding Cost

11-21 Inventory Management

Minimum Total Cost

The total cost curve reaches its minimum

where the carrying and ordering costs are

equal.

Q OPT =

2DS

=

H

2(Annual Demand)(Order or Setup Cost)

Annual Holding Cost

11-22 Inventory Management

Economic Production Quantity (EPQ)

Production done in batches or lots

Capacity to produce a part exceeds the parts

usage or demand rate

Assumptions of EPQ are similar to EOQ

except orders are received incrementally

during production

11-23 Inventory Management

Economic Production Quantity Assumptions

Only one item is involved

Annual demand is known

Usage rate is constant

Usage occurs continually

Production rate is constant

Lead time does not vary

No quantity discounts

11-24 Inventory Management

Economic Run Size

Q0

2DS

p

H p u

11-25 Inventory Management

Total Costs with Purchasing Cost

Annual

Annual

Purchasing

+

TC = carrying + ordering cost

cost

cost

Q

H

TC =

2

DS

Q

PD

11-26 Inventory Management

Total Costs with PD

Cost

Figure 11.7

Adding Purchasing cost

doesnt change EOQ

TC with PD

TC without PD

PD

EOQ

Quantity

Total Cost with Constant Carrying

Costs

11-27 Inventory Management

Figure 11.9

Total Cost

TCa

TCb

Decreasing

Price

TCc

CC a,b,c

OC

EOQ

Quantity

11-28 Inventory Management

When to Reorder with EOQ Ordering

Reorder Point - When the quantity on hand

of an item drops to this amount, the item is

reordered

Safety Stock - Stock that is held in excess of

expected demand due to variable demand

rate and/or lead time.

Service Level - Probability that demand will

not exceed supply during lead time.

11-29 Inventory Management

Determinants of the Reorder Point

The rate of demand

The lead time

Demand and/or lead time variability

Stockout risk (safety stock)

11-30 Inventory Management

Safety Stock

Quantity

Figure 11.12

Maximum probable demand

during lead time

Expected demand

during lead time

ROP

Safety stock reduces risk of

stockout during lead time

Safety stock

LT

Time

11-31 Inventory Management

Reorder Point

Figure 11.13

The ROP based on a normal

Distribution of lead time demand

Service level

Risk of

a stockout

Probability of

no stockout

Expected

demand

0

ROP

Quantity

Safety

stock

z

z-scale

11-32 Inventory Management

Fixed-Order-Interval Model

Orders are placed at fixed time intervals

Order quantity for next interval?

Suppliers might encourage fixed intervals

May require only periodic checks of

inventory levels

Risk of stockout

11-33 Inventory Management

Fixed-Interval Benefits

Tight control of inventory items

Items from same supplier may yield savings

in:

Ordering

Packing

Shipping costs

May be practical when inventories cannot be

closely monitored

11-34 Inventory Management

Fixed-Interval Disadvantages

Requires a larger safety stock

Increases carrying cost

Costs of periodic reviews

11-35 Inventory Management

Single Period Model

Single period model: model for ordering of

perishables and other items with limited

useful lives

Shortage cost: generally the unrealized

profits per unit

Excess cost: difference between purchase

cost and salvage value of items left over at

the end of a period

11-36 Inventory Management

Single Period Model

Continuous stocking levels

Identifies optimal stocking levels

Optimal stocking level balances unit shortage

and excess cost

Discrete stocking levels

Service levels are discrete rather than

continuous

Desired service level is equaled or exceeded

11-37 Inventory Management

Operations Strategy

Too much inventory

Tends to hide problems

Easier to live with problems than to eliminate

them

Costly to maintain

Wise strategy

Reduce lot sizes

Reduce safety stock

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter 06 - ManAcc CabreraDocument17 pagesChapter 06 - ManAcc CabreraNoruie MagabilinNo ratings yet

- How Dna Controls The Workings of The CellDocument2 pagesHow Dna Controls The Workings of The Cellapi-238397369No ratings yet

- Solutions To Irodov's Problems - Volume IIDocument442 pagesSolutions To Irodov's Problems - Volume IIZequinha de Abreu100% (2)

- Chapter 26 - AnswerDocument3 pagesChapter 26 - AnswerAgentSkySkyNo ratings yet

- Management Accounting by CabreraDocument21 pagesManagement Accounting by CabrerachahunayNo ratings yet

- Chapter 25 - AnswerDocument18 pagesChapter 25 - AnswerAgentSkySkyNo ratings yet

- Capital Budgeting Decisions SolutionsDocument6 pagesCapital Budgeting Decisions SolutionsCarmila BaltazarNo ratings yet

- Chapter 24 - AnswerDocument12 pagesChapter 24 - AnswerAgentSkySkyNo ratings yet

- Chapter 19 - AnswerDocument31 pagesChapter 19 - AnswerAgentSkySkyNo ratings yet

- Chapter 22 - AnswerDocument6 pagesChapter 22 - Answerlooter198No ratings yet

- Chapter 23 - AnswerDocument4 pagesChapter 23 - AnswerAgentSkySkyNo ratings yet

- Chapter 18 - AnswerDocument7 pagesChapter 18 - AnswerAgentSkySkyNo ratings yet

- Chapter 24 - AnswerDocument12 pagesChapter 24 - AnswerAgentSkySkyNo ratings yet

- Chapter 20 - AnswerDocument15 pagesChapter 20 - AnswerAgentSkySky100% (1)

- Chapter 21 - AnswerDocument4 pagesChapter 21 - Answerlooter198No ratings yet

- Chapter 16 - AnswerDocument16 pagesChapter 16 - AnswerAgentSkySkyNo ratings yet

- Chapter 13 - AnswerDocument36 pagesChapter 13 - Answerlooter198No ratings yet

- Chapter 15 - AnswerDocument21 pagesChapter 15 - AnswerAgentSkySkyNo ratings yet

- Chapter 14 - AnswerDocument24 pagesChapter 14 - AnswerAgentSkySky100% (1)

- Defining Professional StandardsDocument12 pagesDefining Professional Standardsjessa angelaNo ratings yet

- Chapter 17 - AnswerDocument2 pagesChapter 17 - AnswerAgentSkySkyNo ratings yet

- Chapter 09 - AnswerDocument30 pagesChapter 09 - Answerlooter198No ratings yet

- ACTIVITY-BASED COSTING SOLUTIONS MANUALDocument14 pagesACTIVITY-BASED COSTING SOLUTIONS MANUALlooter198100% (1)

- VARIABLE COSTING SOLUTIONS MANUALDocument20 pagesVARIABLE COSTING SOLUTIONS MANUALAgentSkySkyNo ratings yet

- Ch03-Maintaining Professional Responsibility - Regulation and Legal LiabilityDocument18 pagesCh03-Maintaining Professional Responsibility - Regulation and Legal LiabilityShinny Lee G. UlaNo ratings yet

- Ch01 - Auditing, Attestation, and AssuranceDocument9 pagesCh01 - Auditing, Attestation, and AssuranceRamon Jonathan Sapalaran100% (2)

- Chapter 10 - AnswerDocument15 pagesChapter 10 - AnswerAgentSkySkyNo ratings yet

- Chapter 08 - AnswerDocument17 pagesChapter 08 - AnswerAgentSkySkyNo ratings yet

- Chapter 07 - ManAcc CabreraDocument7 pagesChapter 07 - ManAcc CabreraNoruie MagabilinNo ratings yet

- Chapter 05 - AnswerDocument36 pagesChapter 05 - AnswerAgentSkySkyNo ratings yet

- MGT Chapter 03 - AnswerDocument10 pagesMGT Chapter 03 - Answerlooter198No ratings yet

- Chapter 04 - ManAcc CabreraDocument9 pagesChapter 04 - ManAcc CabreraNoruie MagabilinNo ratings yet

- Excel Dynamic Arrays: Department Item Quantity Price Total $Document5 pagesExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNo ratings yet

- Cantors Paradox PDFDocument16 pagesCantors Paradox PDFColectivo Utopía MoreliaNo ratings yet

- Geophysical Report Megnatic SurveyDocument29 pagesGeophysical Report Megnatic SurveyShahzad KhanNo ratings yet

- Winegard Sensar AntennasDocument8 pagesWinegard Sensar AntennasMichael ColeNo ratings yet

- HowTo Work With CR 90Document87 pagesHowTo Work With CR 90WagBezerraNo ratings yet

- Kalayaan Elementary SchoolDocument3 pagesKalayaan Elementary SchoolEmmanuel MejiaNo ratings yet

- THKDocument1,901 pagesTHKapi-26356646No ratings yet

- 1 05 Lab Crime Scene Sketch GADocument2 pages1 05 Lab Crime Scene Sketch GAthis is hardly gonna be usedNo ratings yet

- Verify scope acceptance of project deliverablesDocument5 pagesVerify scope acceptance of project deliverablesmypmpbooksNo ratings yet

- DasibiOzoneMonitorManual 1008Document183 pagesDasibiOzoneMonitorManual 1008api-26966403100% (2)

- 11+ Entrance Examination: Specimen PaperDocument8 pages11+ Entrance Examination: Specimen PaperNayem Hossain HemuNo ratings yet

- View DsilDocument16 pagesView DsilneepolionNo ratings yet

- Reference Mil-Aero Guide ConnectorDocument80 pagesReference Mil-Aero Guide ConnectorjamesclhNo ratings yet

- PEE3-M Lec 1Document19 pagesPEE3-M Lec 1Ena Leanica DelgadoNo ratings yet

- PDS OperatorStationDocument7 pagesPDS OperatorStationMisael Castillo CamachoNo ratings yet

- 8086 Instruction SetDocument66 pages8086 Instruction SetRaj KumarNo ratings yet

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Document22 pages000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- College of Information Technology Dmmmsu-Mluc City of San FernandoDocument9 pagesCollege of Information Technology Dmmmsu-Mluc City of San FernandoZoilo BagtangNo ratings yet

- Self Report QuestionnaireDocument6 pagesSelf Report QuestionnaireMustafa AL ShlashNo ratings yet

- Affixation (Landscape)Document4 pagesAffixation (Landscape)difafalahudinNo ratings yet

- BetaDocument16 pagesBetaAkshita Saxena100% (2)

- ID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuDocument21 pagesID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuGheaMarisyaPuteriNo ratings yet

- F 2786538d6cdc0bb1Document245 pagesF 2786538d6cdc0bb1Daniel HarutyunyanNo ratings yet

- VRV A 12 PDFDocument1 pageVRV A 12 PDFMoe Thiri ZunNo ratings yet

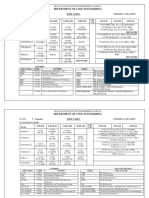

- Time TableDocument7 pagesTime TableChethan .H.GNo ratings yet

- Numeri OrdinaliDocument2 pagesNumeri OrdinaliClaudioNo ratings yet

- Craig Vaughan CHPTR 07Document44 pagesCraig Vaughan CHPTR 07Jorge CananeaNo ratings yet

- Create an access point for non-RouterOS laptop clientsDocument8 pagesCreate an access point for non-RouterOS laptop clientsGorgeus WaffleNo ratings yet