Professional Documents

Culture Documents

All Machine

Uploaded by

Aamer MohammedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All Machine

Uploaded by

Aamer MohammedCopyright:

Available Formats

GATEWAY

Machines&Machining

Issues

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#1

GATEWAY

MaterialRemovalProcess

Mechanical Machining

Turning

Milling

Drilling

Grinding

All hard materials

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#2

GATEWAY

MachiningDOF(DegreesofFreedom)

DOF- # of independently controllable axes of motion-- excluding spindle

rotation or tool translation responsible for cutting.

1 DOF- Drill Press

2 DOF- Lathe

3 DOF- 3 independent axis motions between tool & table

Can use a ball end mill w/ 3 axis machine- for smoothest contour

Following a true 3-D contour requires a minimum of 3 DOF

2 1/2 DOF- 3 independent axes, but can only move 2 at a time

> 3 DOF- Generally allows rotation of spindle wrist or table

Helps keep tool normal to workpiece/ fewer separate fixtures

5 DOF- Minimum to follow any normal at any point

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#3

GATEWAY

TurningOperations

Turning(Performedonlathe)

Partismovingandtoolisstationary.

Usedtomakepartsofroundcrosssection

Screws,shafts,pistons....

Numberofvariouslatheoperations

Turning,facing,boring,drilling,parting,threading

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#4

GATEWAY

LatheComponents

MachineComponents(Mainitems)

Bed:Supportsallothermachineparts

Carriage:Slidesalongthemachineways

Headstock:Powertrainofsystem(spindleincluded)

TailStock:Fixespieceatendoppositetothehead

stock

Swing:Maximumdiameterofthemachinablepiece

Leadscrew:controlsthefeedperrevolutionwitha

greatdealofprecision

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#5

GATEWAY

Lathe

Spindle

Speed

Selector

Headstock

Spindle

Ways

Tool Post

Cross Slide

Carriage (saddle)

Center Tailstock quill

Feed change

gear box

Compound

Rest &

Slide (swivels)

Tailstock

Apron Bed

Lead

Screw

Feed

Rod

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#6

Ref: Fig. 8.52, Kalpakjian. Manufacturing Processes for Engineering Materials 2nd Ed, Addison-Wesley 1991.

GATEWAY

LatheTools

Lathetools

Lefthanded

Righthanded

Threading

Boring

Groove

Parting(CutOff)

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#7

GATEWAY

LatheOperations

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#8

Ref: Fig. 8.51, Kalpakjian. Manufacturing Processes for Engineering Materials 2nd Ed, Addison-Wesley 1991.

GATEWAY

CuttingSpeeds

TypicalLatheCuttingSpeeds

Nominally30800ft./min.

Roughingcuts

Depthofcutgreaterthen.02in

Feedspeedof.008.08in/rev.

FinishingCuts

Lowerthanroughingcuts.

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#9

GATEWAY

Milling

TypesofMillingMachines

HorizontalMillingMachine

VerticalMillingMachine

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#10

GATEWAY

MillCuttingDirection

Cutting direction- Depending on the orientation of the workpiece

feed w.r.t. the rotation of the cutting tool.

Conventional (Up) Milling- Maximum thickness of chip at end of cut

Ref: Figure J-48, Kibbe ,et al. Machine Tool

Practices 5th Ed, Prentice Hall,1995.

Climb (Down) Milling- Maximum thickness of chip at start of cut.

Ref: Figure J-48, Kibbe ,et al. Machine Tool

Practices 5th Ed, Prentice Hall,1995.

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#11

GATEWAY

VerticalKneeMillingMachine

Base and Column- support structure

Knee- Connected to slide on column- can

move up and down

Saddle- Engages slide on top of knee- can

be moved in and out.

Table- Engages slide atop of saddlemoved lengthwise. Holds workpiece.

Ram- Engages swiveling slide atop

column.

Toolhead- Attached to end of ram,

contains motor and quill.

Quill- Non rotating, but contains rotating

spindle. Can be moved up and down.

Ref: Figure 8.69, Kalpakjian. Manufacturing Processes for

Engineering Materials 2nd Ed, Addison-Wesley 1991.

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#12

Ref: Kibbe ,et al. Machine Tool Practices 5th Ed, Prentice Hall,1995, p 550-551

GATEWAY

VerticalMillingMachine

Flexible

Versatile

Newermachines

moreDOF

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#13

GATEWAY

BedMill

Similartoverticalkneemillingmachines

Lessversatilethankneemill

NokneeBeddoesnotmoveupanddown

Verticalmotionpossibleinheadonly

Controllablerangeofmotionofheadlargerthanin

kneemill(totalrangeofmotionless)

Bedmillstifferthankneemill

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#14

GATEWAY

VerticalMillingApplications

Collet

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#15

Ref:ProcessSelection,KGSwiftandJDBooker,p.98.

GATEWAY

ScallopHeightw/BallNosedEndMill

R

y

h

s

d

x

Basic Equation for a circle

- x2 +( Ry)2 =R2

Solving for y.... y=R R2 x2

Max height for

x=( s2)

s 2

2

Thus h=R R 2

(if hd)

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#16

GATEWAY

ScallopHeightBallNoseonanIncline

Edge of cutter described by

x12 +y12 =R2

On previous pass it was

s 2 2

x2 +

+y2 =R2

cos(

)

Setx1 =x2 =x andy1 =y2 =y

s

x=

2cos(

)

h=R

x

R

h

s

(if hd)

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#17

s

y= R2

2cos(

)

2

s

2cos(

)

R2

GATEWAY

HorizontalMillingMachine

COMPONENTS

Base & Column

Knee

Saddle

Table

Spindle

Overarm & Arbor Support

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#18

Ref: Figure 8.68, Kalpakjian. Manufacturing Processes for Engineering Materials 2nd Ed, Addison-Wesley 1991.

GATEWAY

TypesHorizontalMillingOperations

Slab- Axis of cutter //

to workpiece surface

Figure 8.63a, Kalpakjian. Manufacturing Processes for

Engineering Materials 2nd Ed, Addison-Wesley 1991.

Face- Axis of rotation |

to workpiece surface

Figure 8.63b, Kalpakjian. Manufacturing Processes for

Engineering Materials 2nd Ed, Addison-Wesley 1991.

Side- Axis of cutter //

to workpiece surface

Figure 8.67c, Kalpakjian. Manufacturing Processes for

Engineering Materials 2nd Ed, Addison-Wesley 1991.

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#19

GATEWAY

Drilling

Any component requiring cylindrical holes.

Engine Blocks, Machine Components

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#20

Ref:ProcessSelection,KGSwiftandJDBooker,p.104.

GATEWAY

GrindingandAbrasiveProcesses

Abrasive Processes- Generally slower (more

expensive) than other traditional machining

processes. Used on very hard materials, and can

achieve HIGH (virtually unmatched) levels of

precision and finish.

Grinding

Deburring

Honing

Polishing

Lapping

Superfinishing

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#21

GATEWAY

GrindingMachines

Pedestal Grinder

Surface Grinder

Type I- Horizontal spindle w/ reciprocating table

Type II- Horizontal spindle w/ rotary table

Type III- Vertical spindle, table either reciprocates or rotates (blanchard)

Cylindrical Grinder

Center-type

Roll-type- workpiece in bearings rather than on centers

Centerless Grinder- workpiece supported on rest blade, grinding wheel

on one side, regulating wheel on the other

Internal Cylindrical Grinder

Tool Cutting Grinders

Specialty Grinders

Form Grinders and Generating Types

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#22

GATEWAY

SurfaceGrinders

Type I

Type II

Reciprocating

Table

Type III

Rotating

Table

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#23

Ref:

Figures N-1, N-3,N-4, & N-5, Kibbe ,et al. Machine Tool Practices 5th Ed, Prentice Hall,1995.

GATEWAY

CylindricalGrinders

Centerless Type

Center/Roll Type

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#24

Ref: Figures N-8, N-17, N-18, Kibbe ,et al. Machine Tool Practices 5th Ed, Prentice Hall,1995.

GATEWAY

SurfaceRoughness

Surface roughness is generally described with 1 of 2 methods

Ra- Arithmetic Mean Value- the average of the absolute values

of the deviations from the center line of the surface

(n

Ra= |a|+|b|+|c|+|d|+

Rq (formerly RMS)- Root Mean Squared2

2

2

2

Rq = a +b +c +d +...

n

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#25

GATEWAY

RoughnessUnits

Both generally given in micrometers (microns) or

microinches

1Micrometer=1m=1micron=106meters

1Microinch=1in=106inches

1in=0.025m

1m=40in

Humanhair~40m

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#26

GATEWAY

TypicalArithmeticAverageRoughness

Process

micrometers

microinches

Flame Cutting

Snagging (Coarse Grinding)

Sawing

Planing, Shaping

50

25

12.5

2000 1000 500

6.3

250

3.2

125

1.6

63

0.8

32

0.4

16

0.2

8

0.1

4

0.05 .025 .012

2

1

0.5

Average Application

Less Frequent Application

Drilling

Chemical Machining

Electrical-discharge Machining

Milling

Broaching

Reaming

Electron-beam Machining

Laser Machining

Electrochemical Machining

Turning, Boring

Barrel Finishing

Electrochemical Grinding

Roller Burnishing

Grinding

Honing

Electropolishing

Polishing

Lapping

Superfinishing

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#27

Ref: Fig. 8.35, Kalpakjian. Manufacturing Processes for Engineering Materials 2nd Ed, Addison-Wesley 1991.

GATEWAY

Summary

Fourtypesofmechanicalremoval

processes

Turning

Milling

Drilling

Grinding

Finishofworkpiece

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#28

GATEWAY

Credits

Thismoduleisintendedasasupplementtodesignclassesinmechanical

engineering.ItwasdevelopedatTheOhioStateUniversityundertheNSF

sponsoredGatewayCoalition(grantEEC9109794).Contributingmembers

include:

GaryKinzel..Projectsupervisor

ChrisHubertandAlanBonifas.....Primaryauthors

PhuongPhamandMattDetrick...Modulerevisions

L.Pham....Audiovoice

References:

Kalpakjian, Manufacturing Processes for Engineering Materials 2nd Ed,

Addison-Wesley 1991

Kibbe ,et al. Machine Tool Practices 5th Ed, Prentice Hall,1995

Swift,KGandJDBooker, ProcessSelection,Arnold/JohnWiley&SonsInc.,

NewYork,1997

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#29

GATEWAY

Disclaimer

This information is provided as is for general educational purposes; it can

change over time and should be interpreted with regards to this particular

circumstance. While much effort is made to provide complete information,

Ohio State University and Gateway do not guarantee the accuracy and

reliability of any information contained or displayed in the presentation. We

disclaim any warranty, expressed or implied, including the warranties of

fitness for a particular purpose. We do not assume any legal liability or

responsibility for the accuracy, completeness, reliability, timeliness or

usefulness of any information, or processes disclosed. Nor will Ohio State

University or Gateway be held liable for any improper or incorrect use of the

information described and/or contain herein and assumes no responsibility for

anyones use of the information. Reference to any specific commercial

product, process, or service by trade name, trademark, manufacture, or

otherwise does not necessarily constitute or imply its endorsement.

DepartmentofMechanicalEngineering,TheOhioStateUniversity

Sl.#30

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hydrohen Manufacturing From AluminumDocument3 pagesHydrohen Manufacturing From AluminumAamer MohammedNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Thermal - Mixed Boundary Example (Conduction/Convection/Insulated)Document5 pagesThermal - Mixed Boundary Example (Conduction/Convection/Insulated)Amit PalaliyaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Water Splitting MethodDocument2 pagesWater Splitting MethodAamer MohammedNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Follow-Up Report - "Hydrogen Production Breakthrough - BarryOnEnergyDocument10 pagesFollow-Up Report - "Hydrogen Production Breakthrough - BarryOnEnergyAamer MohammedNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Esa2010 c1 BerndtDocument13 pagesEsa2010 c1 BerndtAamer MohammedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Follow-Up Report - "Hydrogen Production Breakthrough - BarryOnEnergyDocument10 pagesFollow-Up Report - "Hydrogen Production Breakthrough - BarryOnEnergyAamer MohammedNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- How To Build A Happy FamilyDocument148 pagesHow To Build A Happy FamilyMia Delos Santos100% (9)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Notification AAI Manager Junior ExecutiveDocument8 pagesNotification AAI Manager Junior ExecutivesreenuNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Joshua Becker-Simplify 2011 PDFDocument80 pagesJoshua Becker-Simplify 2011 PDFTina SimoglouNo ratings yet

- Hydrohen Manufacturing From AluminumDocument3 pagesHydrohen Manufacturing From AluminumAamer MohammedNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Water Splitting MethodDocument2 pagesWater Splitting MethodAamer MohammedNo ratings yet

- Syllabus Waste Heat Recovery: Classification, Advantages and Applications, CommerciallyDocument18 pagesSyllabus Waste Heat Recovery: Classification, Advantages and Applications, Commerciallyalzewam152100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RRB JE CBT1 - 2 Mechanical PDFDocument865 pagesRRB JE CBT1 - 2 Mechanical PDFshankarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Water As A Fuel: Name:-Asif Shakeel ShaikhDocument10 pagesWater As A Fuel: Name:-Asif Shakeel ShaikhAamer MohammedNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Self Attendance Report for SOHEL ABDUL HFEEZ MOHAMMAD BE-CIVIL-A 2017-2018(SEMESTER VIIIDocument1 pageSelf Attendance Report for SOHEL ABDUL HFEEZ MOHAMMAD BE-CIVIL-A 2017-2018(SEMESTER VIIIAamer MohammedNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- IES Syllabus For Mechanical Engineering ME PDFDocument3 pagesIES Syllabus For Mechanical Engineering ME PDFvenuNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Combine Result 2Document18 pagesCombine Result 2Aamer MohammedNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Aim: To Study Various Type of Compressors. TheoryDocument6 pagesAim: To Study Various Type of Compressors. TheoryAamer MohammedNo ratings yet

- Form 4 driving licence applicationDocument2 pagesForm 4 driving licence applicationAamer MohammedNo ratings yet

- Shaper SlottingDocument34 pagesShaper SlottingAamer MohammedNo ratings yet

- WASTE HEAT RECOVERY (HRSG) PerformanceDocument17 pagesWASTE HEAT RECOVERY (HRSG) PerformanceEjaz AhmedNo ratings yet

- Aim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryDocument8 pagesAim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryAamer MohammedNo ratings yet

- Process TechnologyDocument74 pagesProcess TechnologyKashif MirzaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SmotorDocument20 pagesSmotorAamer MohammedNo ratings yet

- RESULT TITLEDocument5,953 pagesRESULT TITLEAamer MohammedNo ratings yet

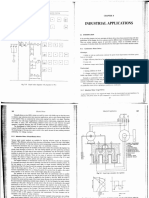

- Chapter 6Document14 pagesChapter 6Aamer MohammedNo ratings yet

- Machining Process Used To Produce Various ShapesDocument33 pagesMachining Process Used To Produce Various ShapesAamer MohammedNo ratings yet

- KB - ETA - Printable - PDF - VNX Drive Firmware UpgradeDocument5 pagesKB - ETA - Printable - PDF - VNX Drive Firmware UpgradeAshley DouglasNo ratings yet

- ALKO Case StudyDocument32 pagesALKO Case Studylordponch0% (2)

- Standard Hardwood Pallet SpecsDocument2 pagesStandard Hardwood Pallet SpecsmnnfzNo ratings yet

- Data Governance Case Study Ciba FinalDocument37 pagesData Governance Case Study Ciba FinalAbdelhamid HarakatNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- SS 671Document9 pagesSS 671OwNo ratings yet

- SAS Institute A00-250Document21 pagesSAS Institute A00-250rajeshmsitNo ratings yet

- Hydrotite Brochure Mar08-GreenstreakDocument4 pagesHydrotite Brochure Mar08-GreenstreakBudi TooleeNo ratings yet

- Crack WidthDocument4 pagesCrack Widthmdelacua267% (3)

- 2009 UAV Project DescriptionDocument2 pages2009 UAV Project Descriptionjohnyb111No ratings yet

- Engineers Guide CFRP Monocoque DesignDocument24 pagesEngineers Guide CFRP Monocoque DesignShivam Wankhede100% (1)

- PLM SyllabusDocument1 pagePLM SyllabusGobivel KathirvelNo ratings yet

- BS en 10137-3-1996Document14 pagesBS en 10137-3-1996Martijn GrootNo ratings yet

- McGraw-Hill’s Handbook of Transportation Engineering Chapter 12: Traffic Congestion SolutionsDocument30 pagesMcGraw-Hill’s Handbook of Transportation Engineering Chapter 12: Traffic Congestion Solutionsdave4359No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Software Engineering Question BankDocument7 pagesSoftware Engineering Question Banksubhapam100% (1)

- QFEST Proceedings 2017Document229 pagesQFEST Proceedings 2017GogyNo ratings yet

- Master Ceramico OX - English - Rev-DDocument2 pagesMaster Ceramico OX - English - Rev-DfaniaaaNo ratings yet

- MAX17077AETM 1tDocument1 pageMAX17077AETM 1tAlejandro clericoNo ratings yet

- April 2014 1396445255 131fa 88 PDFDocument2 pagesApril 2014 1396445255 131fa 88 PDFkavithaNo ratings yet

- V. ProgrammesDocument23 pagesV. ProgrammesSharan AnnapuraNo ratings yet

- Vision, Mission and SWOT of Tata NanoDocument5 pagesVision, Mission and SWOT of Tata NanoSaprem KulkarniNo ratings yet

- Faurecia Automotive Maneser NSF Project Time Plan PS Trails (6152)Document2 pagesFaurecia Automotive Maneser NSF Project Time Plan PS Trails (6152)Tushar KohinkarNo ratings yet

- JIT FullDocument6 pagesJIT FullSuguna SubramaniamNo ratings yet

- FXG (FG-FXG) : Duplex Power PumpDocument2 pagesFXG (FG-FXG) : Duplex Power PumpJose Alberto Escalante MedinaNo ratings yet

- Lifecycle of A Project Management: Prepared By: Rosida Binti Ahmad (Psa) 1Document55 pagesLifecycle of A Project Management: Prepared By: Rosida Binti Ahmad (Psa) 1Nik AliffNo ratings yet

- 57 Parker Filtration CatalogueDocument308 pages57 Parker Filtration CatalogueAvinNo ratings yet

- Certification of Engine Usage Monitoring SystemsDocument12 pagesCertification of Engine Usage Monitoring SystemsRamprasad SrinivasanNo ratings yet

- TBC Catalogue No8 July 07 - PDF Small For WebsiteDocument202 pagesTBC Catalogue No8 July 07 - PDF Small For WebsitesandulupeniNo ratings yet

- ServiceManuals LG Washing WD1015FB WD-1015FB Service ManualDocument35 pagesServiceManuals LG Washing WD1015FB WD-1015FB Service ManualMicu Adrian DanutNo ratings yet

- EstimateDocument6 pagesEstimateSansar PanchalNo ratings yet

- Cif PmiDocument1 pageCif PmiC.K DavisNo ratings yet